洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

快速查找中频炉故障的简要步骤

厂家在使用中频感应炉的过程中总会出现这样或者那样的问题,作为专业维修中频炉的电工,遇到中频炉故障时该如何快速检查判断出故障原因,从而拟定维修方案,这是考验中频电工的重要指标。以下是一位在铸造企业负责电炉检修15年的老电工总结的快速检查和维修中频感应炉故障的方法。

一般情况下,操作工人可以把中频感应炉出现的故障根据故障现象划分为两种,一种是完全不能启动,另一种是启动后不能正常工作。按照一般的原则,在故障出现之后,必须在断开电源的时候对中频感应炉的整个系统进行全面的检查,确保操作安全。

这样的全面检查分为以下几个内容:第一个是电源,要用万用表测量一下主要电路的开关,以及接通保险丝之后是否有电流通过,这样的方法能够排除这些元件发生了断路的可能性。

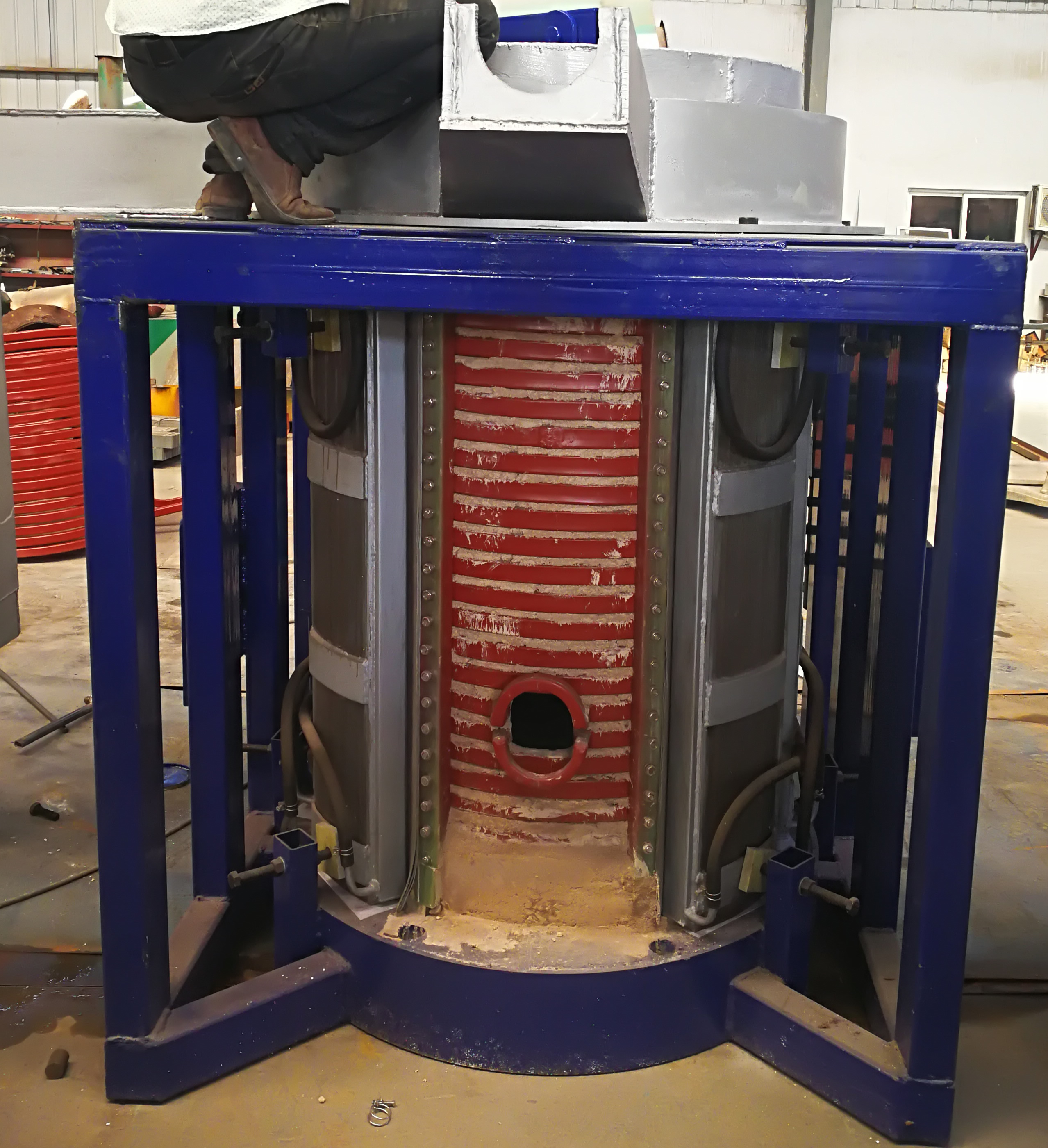

接下来,检查整流器是不是处于正常的工作状态,整流器使用三相全控桥式整流电路,这种电路包括6个快速熔断器,6个晶闸管和6个脉冲变压器以及一个续流二极管。

最后检查快出熔断器,在快速熔断器上面有一个红色的指示器,正常的时候指示器缩在外壳内,在快熔化烧断的时候它就会弹出来。然而有一些指示器安装的时候比较紧,所以在熔化后并没有弹出而是卡在里面,所以为了安全起见仍然应该用万用表断档测试一下。

通过以上的几个方面的检测,基本可以快速定位到故障元件,然后根据具体的故障现象拟定维修方案。

Quick steps to quickly find faults in the intermediate frequency furnace

In the process of using the medium frequency induction furnace, the manufacturer always has such problems or the like. As an electrician who professionally repairs the intermediate frequency furnace, how to quickly check and determine the cause of the failure when encountering the failure of the intermediate frequency furnace, so as to formulate the maintenance plan, this is the test of the intermediate frequency. An important indicator of electricians. The following is a method for quickly checking and repairing the fault of the intermediate frequency induction furnace summarized by the old electrician who is responsible for the electric furnace maintenance for 15 years.

Under normal circumstances, the operator can divide the faults in the intermediate frequency induction furnace into two types according to the fault phenomenon. One is that it cannot be started at all, and the other is that it cannot work normally after starting. According to the general principle, after the fault occurs, the entire system of the intermediate frequency induction furnace must be thoroughly checked when the power is turned off to ensure safe operation.

Such a comprehensive inspection is divided into the following contents: The first one is the power supply. It is necessary to measure the switch of the main circuit with a multimeter and whether there is current passing after the fuse is turned on. This method can eliminate the possibility of disconnection of these components. .

Next, check that the rectifier is in normal operation. The rectifier uses a three-phase full-control bridge rectifier circuit. This circuit includes six fast-blowers, six thyristors and six pulse transformers, and one free-wheeling diode.

Finally, check that the fuse is coming out. There is a red indicator on the fast fuse. When normal, the indicator shrinks into the outer casing and it will pop up when it melts and burns. However, some indicators are tight when installed, so they do not pop up after being melted but are stuck inside, so for safety reasons, you should still use a multimeter to test.

Through the above aspects of detection, it is basically possible to quickly locate the faulty component, and then formulate a maintenance plan according to the specific fault phenomenon.

http://www.firstfurnace.com/BdwlkjNews.asp?id=1460

手 机:15038554363