洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

一.技术说明

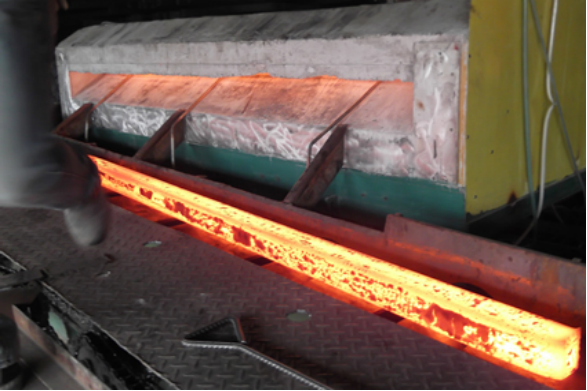

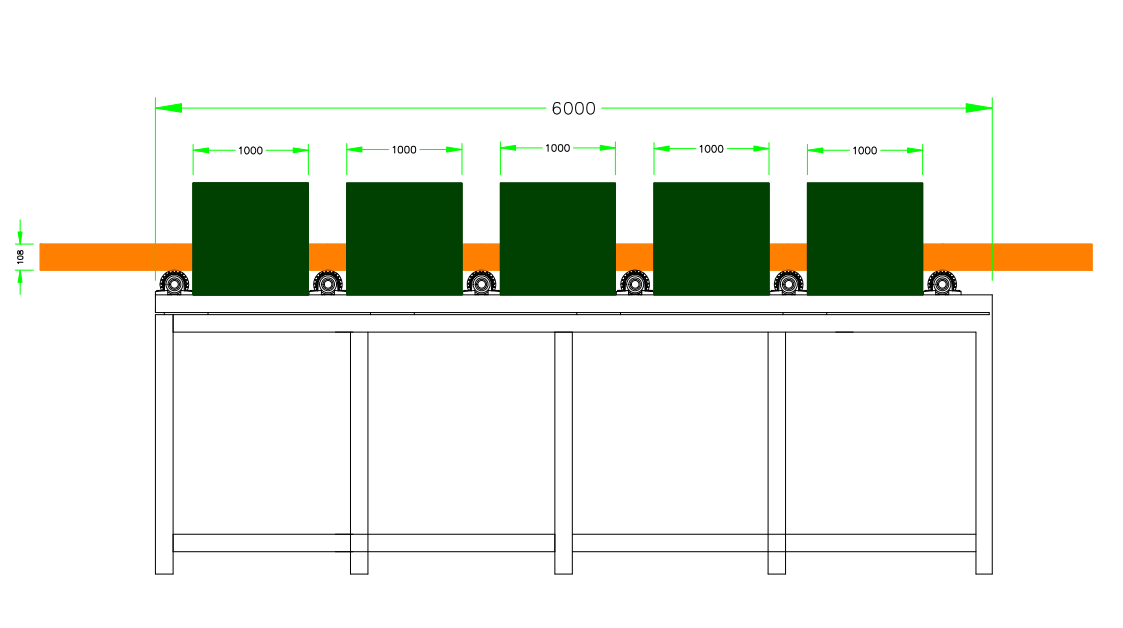

被加热料参数:160MM*160MM L=2M ,150MM*160MM L=2M

120MM*120MM L=2M

加热长度:2M 加热重量约为:400 Kg

加热温度有800。C加热至1250。C

每小时产量18吨 加热节拍为80秒 /件

二、中频电源技术参数

|

钢坯加热炉型号 |

技术指标 |

|

钢坯加热炉额定功率 |

1500KW-3000KW |

|

进相电压 |

380V-660V |

|

相数 |

3 |

|

电炉额定电压 |

1100-1250V |

|

额定电流 |

1700A |

|

额定频率 |

500HZ |

|

额定温度 |

1250℃ |

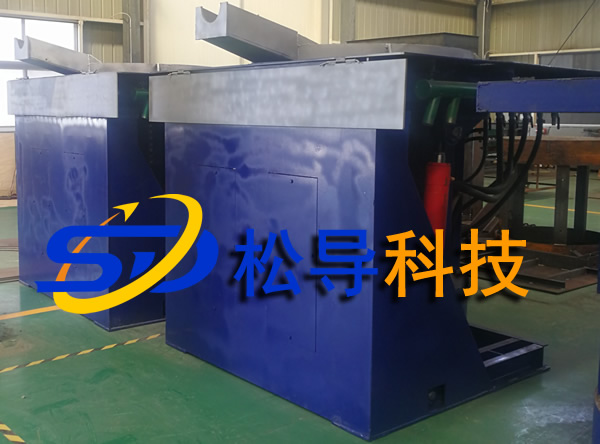

三、整套钢坯加热炉说明

感应器加热速度快,加热温度均匀,氧化损耗少,金属成分均匀。

可从冷炉直接加热,更换品种方便。

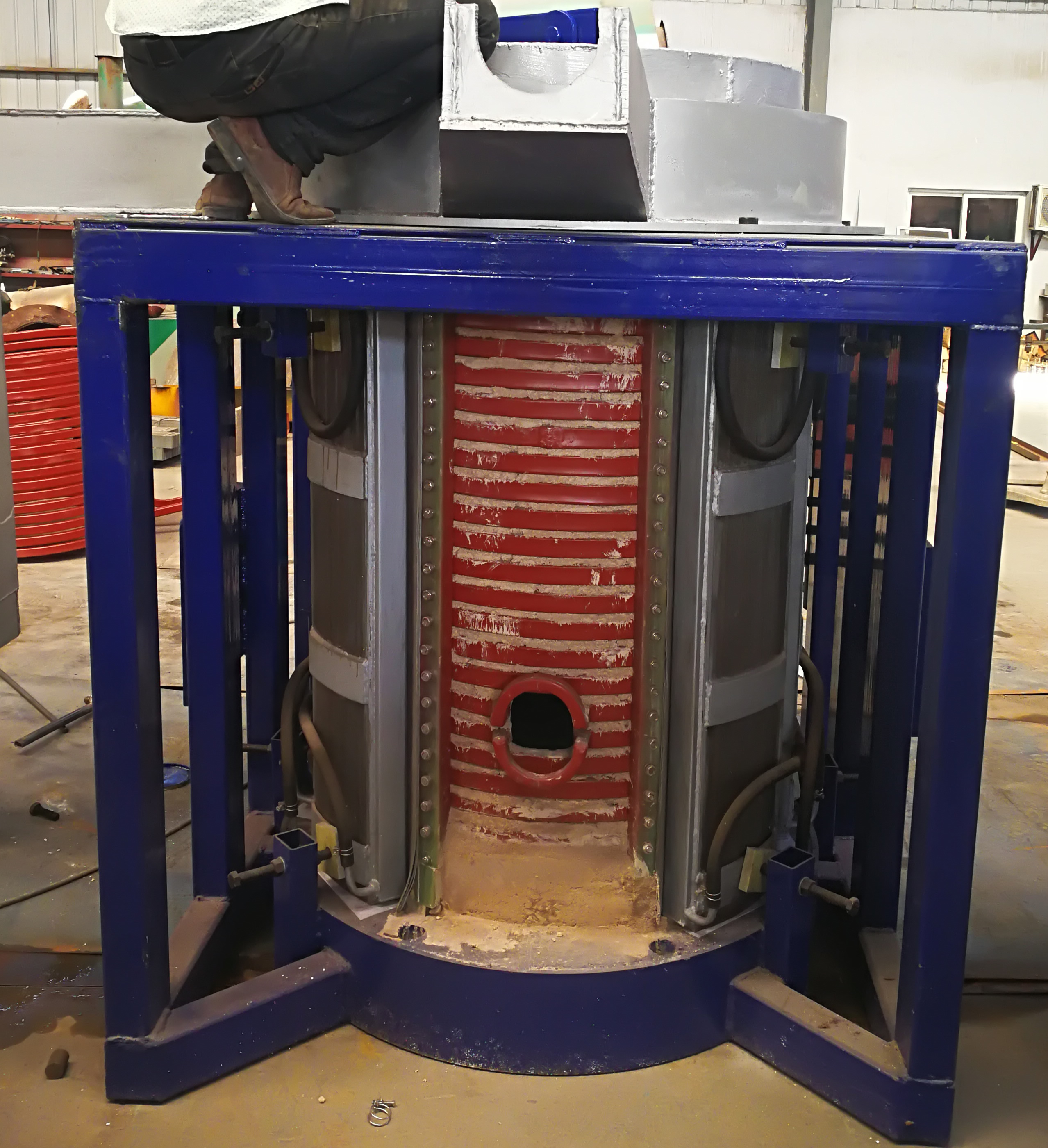

精湛的线圈设计,优质的厚壁铜管,通过合理选择感应圈的匝间距离使得感应圈的转换效率最高,电阻最小,更多的能量可用于加热,强度高,线圈不易发生因电弧和膨胀力而引起损坏。

牢固的线圈支撑系统,使得每匝线圈都牢牢的锁紧,消除匝间断路可能。

四、成套钢坯加热炉组成

|

序号 |

钢坯加热炉名称 |

规格型号 |

数量 |

备 注 |

|

1 |

中频电源 |

KGPS3000KW- |

2套 |

|

|

2 |

补偿电容 |

3000KW |

2组 |

|

|

3 |

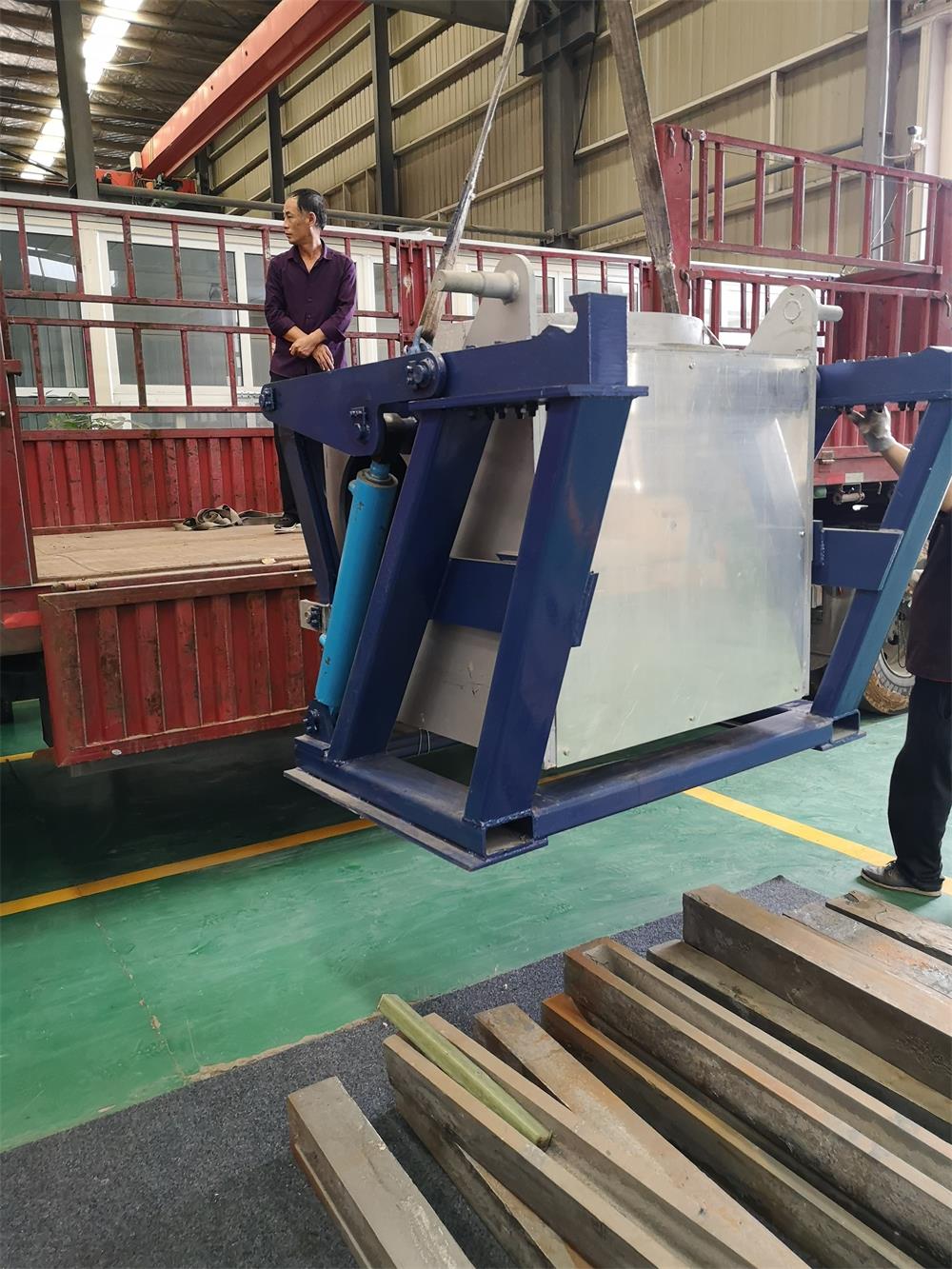

透热炉支架 |

WL—JRZ-1 |

1套 |

|

|

4 |

连接水冷电缆 |

SDL-1000 |

4根 |

|

|

5 |

透热感应器 |

160×160 |

1套 |

80S/件 |

First. Technical description

Parameters of the material to be heated: 160MM*160MM L=2M , 150 MM*160MM L=2M

120MM*120MM L=2M

Heating length: 2M Heating weight: about 400 Kg

The heating temperature is 800 . C is heated to 1250 . C

18 tons per hour, the heating beat is 80 seconds / piece

Second, the intermediate frequency power supply technical parameters

|

Billet heating furnace model |

Technical indicators |

|

Billet furnace rated power |

1500KW -3000 KW |

|

Phase voltage |

380V- 660V |

|

Phase |

3 |

|

Electric furnace rated voltage |

1100-1250V |

|

Rated current |

1700A |

|

Rated frequency |

500 HZ |

|

Rated temperature |

1250 ° C |

Third, the entire set of billet heating furnace description

The inductor has a fast heating speed , a uniform heating temperature, less oxidation loss, and uniform metal composition.

It can be directly heated from a cold furnace and is easy to change.

Exquisite coil design, high-quality thick-walled copper tube, through the reasonable choice of the inter-turn distance of the induction coil, the induction coil has the highest conversion efficiency, the smallest resistance, more energy can be used for heating, high strength, the coil is not easy to occur due to arc and expansion Damage caused by force.

Robust coil support system, so that each turn of the coil are firmly locked to eliminate possible path turns intermittently.

Fourth, Complete set of billet heating furnace

|

Serial number |

Billet heating furnace name |

Specification model |

Quantity |

Remarks |

|

1 |

Intermediate frequency power supply |

KGPS 3 000KW - |

2 sets |

|

|

2 |

Compensation capacitor |

3 000 KW |

2 teams |

|

|

3 |

Diathermy furnace bracket |

WL-JRZ-1 |

1 set |

|

|

4 |

Connecting water-cooled cable |

SDL-1000 |

4 roots |

|

|

5 |

Diathermy sensor |

160×160 |

1 set |

80S/piece |

http://www.firstfurnace.com/BdwlkjProduct.asp?id=377

http://www.firstfurnace.com/BdwlkjProduct.asp?id=369

http://www.firstfurnace.com/BdwlkjProduct.asp?id=403

http://www.tecfurnace.com/a/cpzx/steel_billets_production_line/2018/1113/436.html

http://www.tecfurnace.com/a/cpzx/steel_billets_production_line/2018/1113/435.html

手 机:15038554363