洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

弯头弯管用的新型感应中频加热炉

目前国内采用冲压方法生产的弯头,胎具压痕严重,壁厚不均,几何角度超差,质量低,劳动强度大;用同径冷推制方法生产的弯头弯管外弧拉伸减薄,内弧增厚,壁厚不均,机械平口加工量大,浪费原材料,生产效率低,有局限性,无法生产大、中口径中、高压180弯头;用中频感应淬火变压器单双圈加热方法扩径推制的无缝弯头、弯管只能生产直径426mm的规格型号中小口径的碳钢、合金钢弯头,无法生产其他金属材料的弯头、弯管。以上三种生产弯头弯管的方法都满足不了生产大中口径低、中、高压各种材质规格型号的无缝弯头、弯管的需要。

新型感应中频加热炉提供一种能克服现有技术的上述缺陷,能生产有色金属铜、钛、镍、铝及它们的合金和不锈钢、合金钢、碳钢等金属材料的各种规格型号高、中、低压大、中、小口径等壁厚高质量无缝弯头弯管的中频感应多圈加热炉。

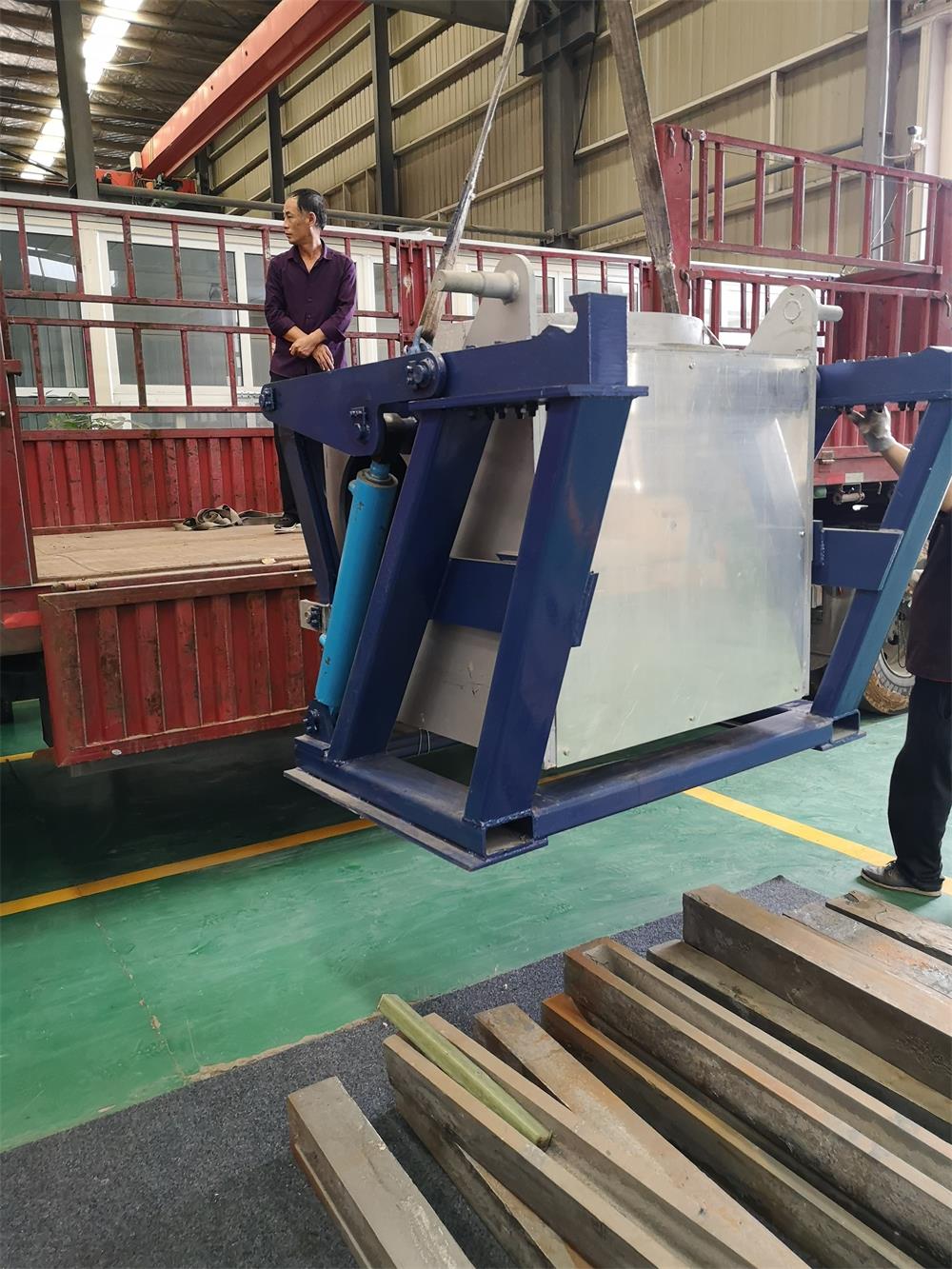

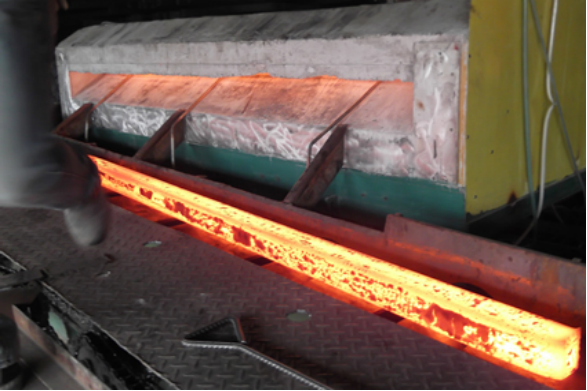

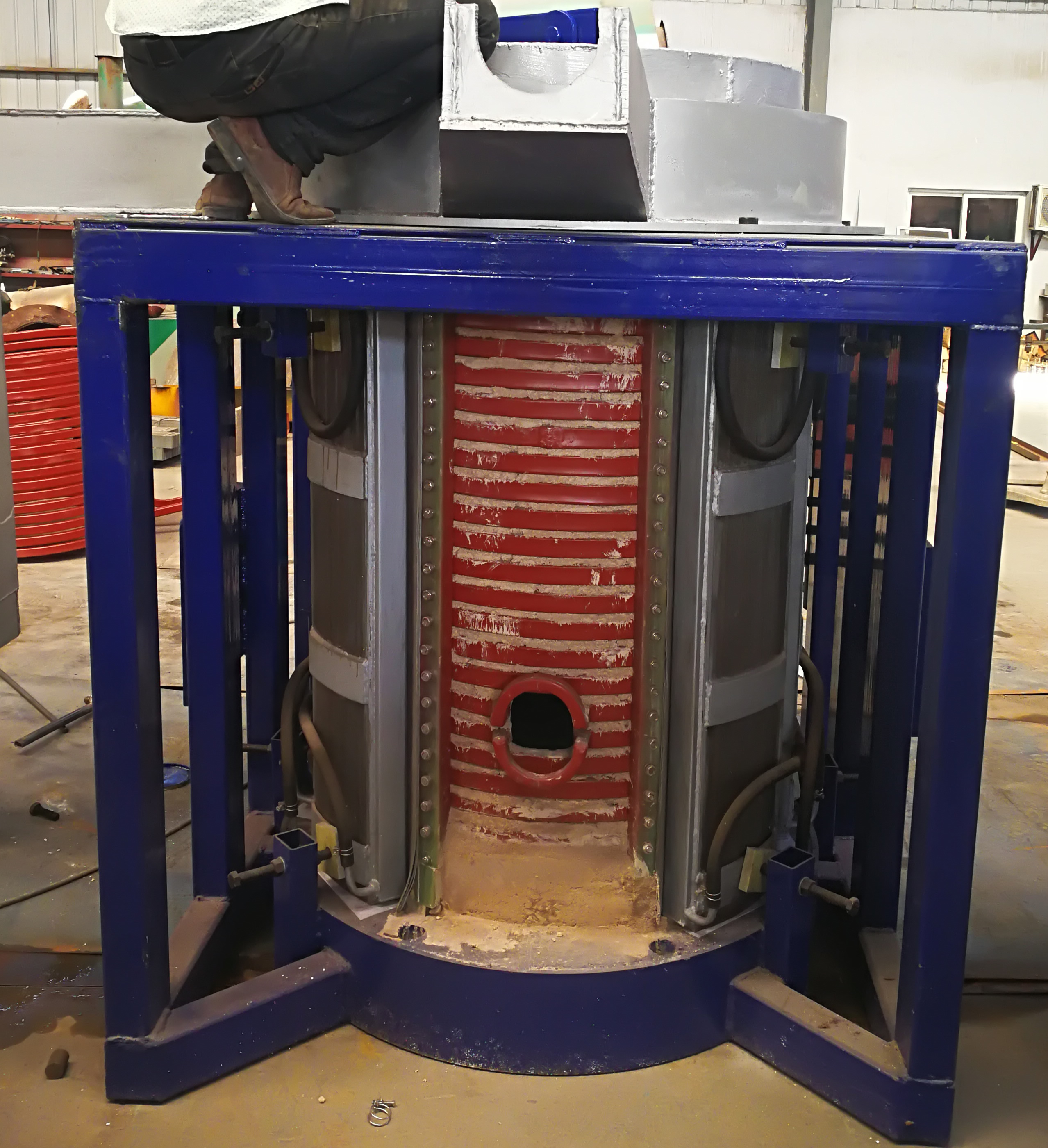

弯头弯管用的新型感应中频加热炉:它包括活动支架和加热炉,加热炉是用紫铜管制成的锥形多圈加热圈,锥形多圈加热圈的两侧各有一个具有一定曲率半径的弧形绝缘板,绝缘板与锥形多圈加热圈之间用螺栓连接固定,锥形多圈加热圈的两端有接线柱与中频电源连接,两侧的绝缘板分别通过圆环和开式索具螺旋扣连接吊装在活动支架的活动滑块上,以便于前后左右上下移动。优点是炉温可以达到1250度,炉温恒定可调,安装方便,宜于移动。通用性强,安全,可靠。产品内外表面光滑,等壁厚,几何角度好,生产效率高,可满足扩径推制m 32-820mm称壁厚Sch5s-Sch160及特厚壁有色金属及不锈钢、合金钢、碳钢等金属材料的各种规格型号高中低压450-900-180无缝弯头弯管或扩径推制各种金属材料的无缝管用,还可热扩径和同径推制DN800-DN3500直缝焊管及螺旋管45度-90度-180度.弯头弯管用。

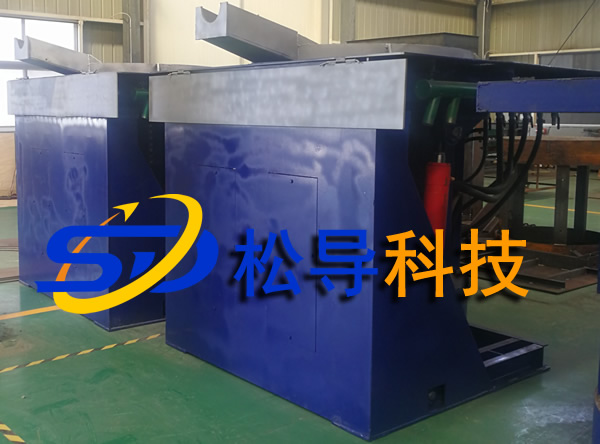

附图说明:

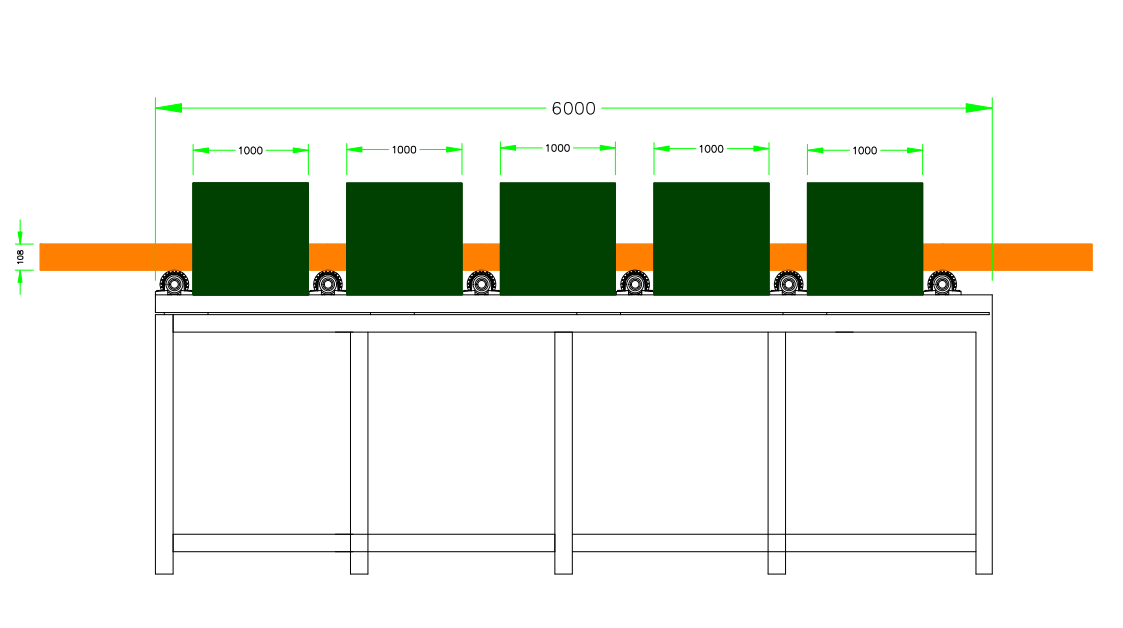

图1是的主视示意图。

图2是的俯视示意图。

具体实施方式:参照图1图2,多圈感应中频加热炉包括活动支架6,加热炉是用紫

铜管制成的锥形多圈加热圈1,锥形多圈加热圈的两侧各有一个具有一定曲率半

径的弧形绝缘板2,绝缘板的曲率半径要与所生产的产品的曲率半径相一致,绝

缘板与锥形多圈加热圈之间用螺栓连接固定,锥形多圈加热圈的两端有接线柱

7,两侧的绝缘板分别通过圆环3和开式索具螺旋扣4连接吊装在活动支架的活

动滑板块5上。

http://www.songdaokeji.com/plus/list.php?tid=42

http://www.songdaokeji.com

http://www.songdaokeji.com/plus/list.php?tid=52

New induction heating furnace for elbow pipe

At present, the domestic elbow produced by stamping method has serious mold indentation, uneven wall thickness, out-of-poor geometric angle, low quality, and high labor intensity; the elbow elbow produced by the same diameter cold push method is drawn by the outer arc Thinning, thickening of the inner arc, uneven wall thickness, large processing volume of mechanical flat mouth, waste of raw materials, low production efficiency, and limitations, unable to produce large and medium diameter medium and high voltage 180 elbows; medium frequency induction hardening transformer single and double The seamless elbows and elbows made by expanding the diameter of the ring heating method can only produce small and medium-sized carbon steel and alloy steel elbows with a diameter of 426mm, but cannot produce elbows and elbows of other metal materials. The above three methods of producing elbows and elbows can not meet the needs of producing seamless elbows and elbows of various material specifications and models of large and medium caliber, low, medium and high pressure.

The new induction heating furnace provides a high- and medium-sized model that can overcome the above-mentioned shortcomings of the prior art and can produce non-ferrous metals such as copper, titanium, nickel, aluminum and their alloys and stainless steel, alloy steel, carbon steel and other metal materials. , Low-pressure large, medium, small diameter and other high-quality seamless elbow elbow wall thickness and intermediate frequency induction multi-turn heating furnace.

A new type of induction heating furnace for elbow pipes: it includes a movable support and a heating furnace. The heating furnace is a conical multi-circle heating ring made of red copper pipes. Each side of the conical multi-circle heating ring has a certain radius of curvature. The arc-shaped insulating plate is fixed with bolts between the insulating plate and the conical multi-circle heating ring. The two ends of the conical multi-circle heating ring are connected with the intermediate frequency power supply. The insulating plates on both sides pass through the ring and open respectively. The type rigging screw buckle connection is hoisted on the movable sliding block of the movable bracket, so as to move forward, backward, left, and right. The advantage is that the furnace temperature can reach 1250 degrees, the furnace temperature is constant and adjustable, the installation is convenient, and it is suitable for moving. Strong versatility, safety and reliability. The inner and outer surfaces of the product are smooth, with equal wall thickness, good geometric angle, and high production efficiency, which can meet the requirements of m 32-820mm wall thickness Sch5s-Sch160 and extra-thick wall non-ferrous metals, stainless steel, alloy steel, carbon steel and other metal materials A variety of specifications and models of high, medium and low pressure 450-900-180 seamless elbow elbow or expanded diameter to push seamless pipes of various metal materials, can also be thermally expanded and the same diameter to push DN800-DN3500 straight seam welded pipes and spirals Pipe 45 degrees -90 degrees -180 degrees. Elbows are used for elbows.

Description of the drawings:

Figure 1 is a schematic front view.

Figure 2 is a schematic top view.

DETAILED DESCRIPTION: Referring to Figures 1 and 2, the multi-turn induction heating furnace includes a movable support 6, and the heating furnace is made of purple

Conical multi-circle heating ring 1 made of copper tube, one on each side of the conical multi-circular heating ring has a certain curvature and a half

The radius of curvature of the insulating plate 2 must be the same as the radius of curvature of the product being produced.

The edge plate and the tapered multi-turn heating ring are connected and fixed by bolts, and the two ends of the tapered multi-turn heating ring are equipped with terminal posts.

7. The insulating plates on both sides are connected to the movable support by the ring 3 and the open rigging screw buckle 4 respectively.

Move the slide block 5 on.

手 机:15038554363