洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

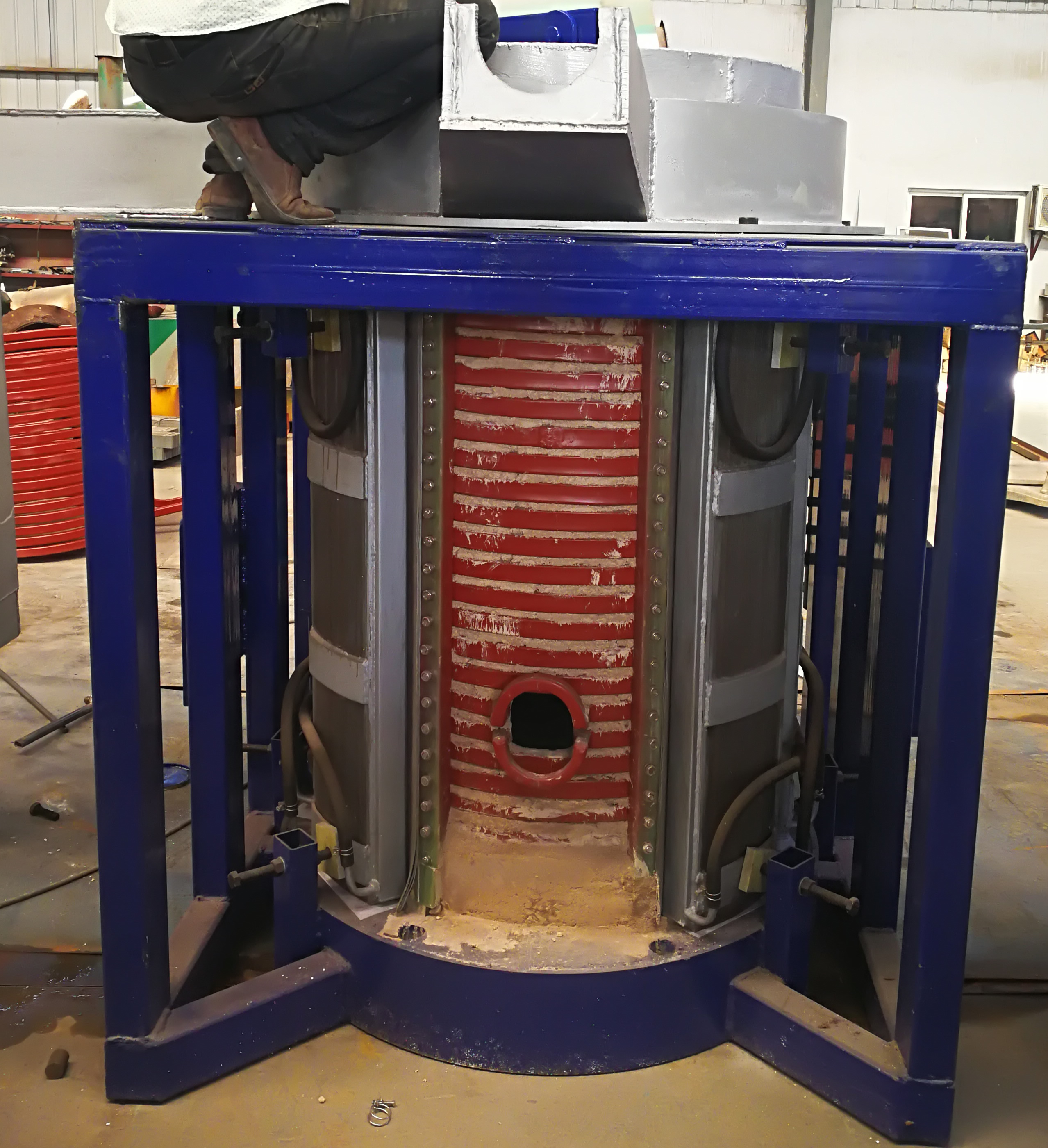

感应加热炉的线圈是怎样制作的?

在绕制感应加热炉的线圈之前,先对纯铜管进行退火。将纯铜管在650 ~ 700℃保温30~40min,然后在20 -30%:的水中快速冷却。加热设备最好用电阻炉。

(1)绕制。将纯铜管绕制成感应加热炉的线圈。在绕制时应用铁模或木模,考虑到铜管 绕制后有回弹量,故应使模具的尺寸稍小于所要求的尺寸。当绕制半径较小时, 应进行热绕,即在绕制时用乙決火焰去烘烤弯曲部位的纯铜管。

(2)校正。将绕制后的感应加热炉的线圈校正到所要求的尺寸,并用夹具压紧。

(3)退火。感应加热炉的线圈退火温度、时间与方式和纯铜管退火相同。

(4)水压试验。在感应加热炉的线圈的纯铜管中通入压力为给水设计压力1.5倍的水或空 气,检査纯铜管与管子接头处是否有漏水现象。

(5)包绝缘层。在纯铜管上重叠绕无碱玻璃丝带。

(6)浸绝缘漆。将包了绝缘层的感应加热炉的线圈在电阻炉或热风烘干箱中预热,然后浸 有机绝缘漆,浸漆时间为15min。在浸漆过程中如果漆中气泡很多,则应延长浸 漆时间,一般浸漆三次。

(7)烘干。在电阻炉或热风烘干箱中进行。感应加热炉的线圈装炉时炉温不应高于50℃, 并以15°C/h的速度升温,至100-110℃时烘干20h,但应以烘至漆膜不粘手为止。最后将已制好的导磁体与感应加热炉的线圈装配成完整的感应器。

How is the coil of the induction heating furnace made?

Before winding the coil of the induction heating furnace, the pure copper tube is annealed. Keep the pure copper tube at 650-700℃ for 30-40min, and then quickly cool it in 20-30%: water. The heating equipment is preferably a resistance furnace.

(1) Winding. The pure copper tube is wound into the coil of the induction heating furnace. Use iron or wood molds when winding. Considering the springback of the copper tube after winding, the size of the mold should be slightly smaller than the required size. When the winding radius is small, hot winding should be carried out, that is, the pure copper tube at the bending part should be baked with a flame in the winding.

(2) Correction. Correct the coil of the wound induction heating furnace to the required size and press it with a clamp.

(3) Annealing. The coil annealing temperature, time and method of induction heating furnace are the same as those of pure copper tube annealing.

(4) Hydrostatic test. Pass water or air with a pressure 1.5 times the design pressure of the feedwater into the pure copper pipe of the coil of the induction heating furnace, and check whether there is any water leakage at the joint between the pure copper pipe and the pipe.

(5) Insulating layer. Overlap the alkali-free glass ribbon on the pure copper tube.

(6) Dip insulating varnish. Preheat the coil of the induction heating furnace covered with an insulating layer in a resistance furnace or a hot air drying box, and then immerse it in an organic insulating varnish for 15 minutes. If there are many bubbles in the paint during the dipping process, the dipping time should be extended, generally three times.

(7) Drying. It is carried out in a resistance furnace or a hot air drying box. When the coil of the induction heating furnace is installed, the furnace temperature should not be higher than 50°C, and the temperature should be raised at a rate of 15°C/h, and it should be dried for 20 hours at 100-110°C, but it should be baked until the paint film does not stick to the hands. Finally, the prepared permeable magnet and the coil of the induction heating furnace are assembled into a complete inductor.

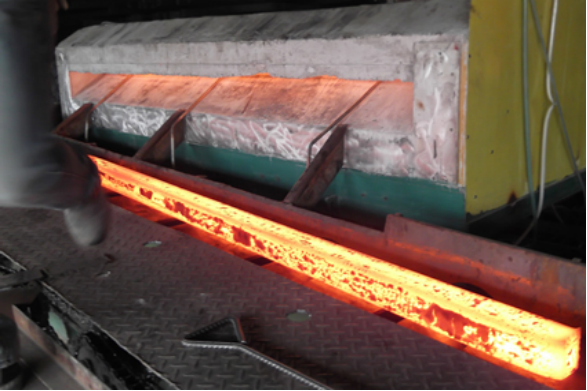

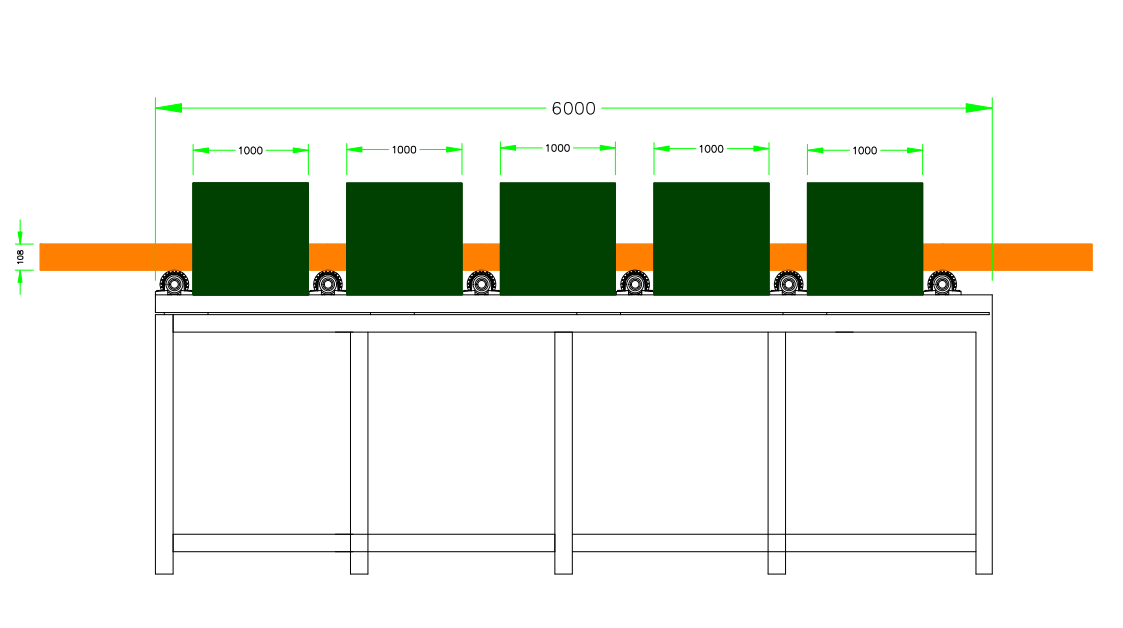

Recommend: induction heating furnace for forging

手 机:15038554363