洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

感应加热焊缝热处理方法

焊缝需要通过热处理来改善力学性能的钢类中主要是管线钢。 不同强度钢级使用的钢类及其对室温强度的要求列于表6-2中。以表6-2中所列的钢类和力学性能可知,提高焊缝综合性能的主要热 处理方法有正火处理、正火+回火处理、淬火+回火处理等方法。 目前国内焊管生产中多釆用焊缝正火处理,其他热处理方法尚未见 采用。最先进的焊缝热处理是淬火和回火生产线。国外大型焊 管生产线中多采用正火处理,调质处理只有日本和欧盟个别公司采用。感应加热调质处理焊缝是今后发展的方向。

表6-2管线钢的标准钢级与室温强度

|

GB/T 9711. 1—1997 钢级 |

API spec 5L—2004 钢级 |

室温力学性能 |

钢类 |

|

|

%/MPa |

ffb/MPa |

|||

|

一 |

A25 |

172 |

310 |

|

|

L210 |

A |

207 |

331 |

碳素钢 |

|

L245 |

B |

241 |

413 |

|

|

L290 |

X42 |

289 |

413 |

|

|

L320 |

X46 |

317 |

434 |

普通低合金钢 |

|

L360 |

X52 |

358 |

455 |

|

|

L390 |

X56 |

386 |

489 |

|

|

L415 |

X60 |

415 |

517 |

低合金高强度钢 |

|

L45O |

X65 |

448 |

530 |

|

|

L485 |

X70 |

482 |

565 |

|

|

L555 |

X80 |

551 |

620 |

微合金化高强度钢 |

|

— |

X100 |

727 |

837 |

|

-

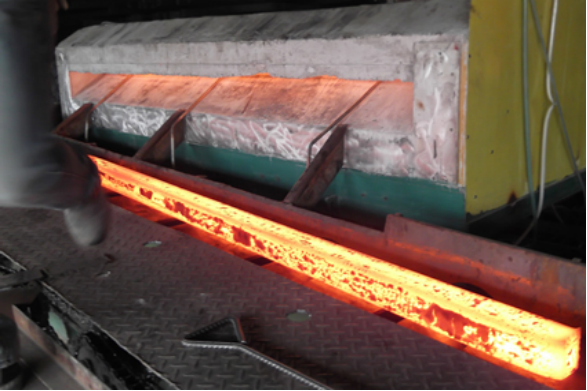

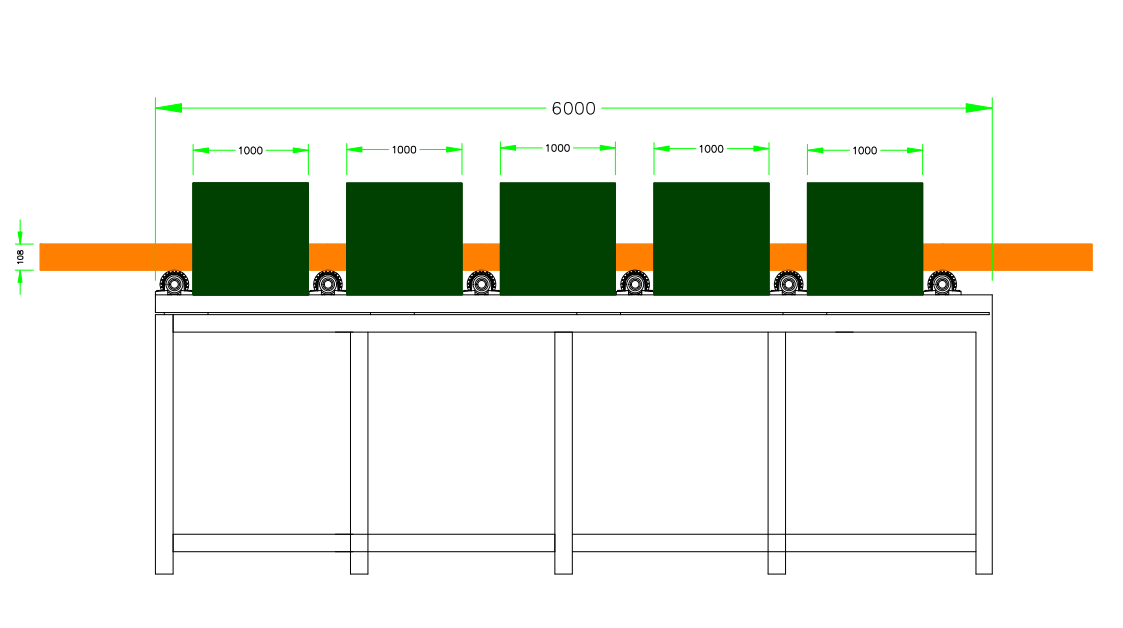

焊缝感应加热正火处理焊缝正火处理中包括退火处理, 有时又称为消除应力退火。焊缝感应加热正火处理是将焊缝加热到 Ae以上温度,900~950°C后空冷至400°C以下水冷到常温。借此 消除焊接内应力,细化焊缝晶粒,改善显微组织,提高焊缝的塑性 和冲击韧性。焊缝感应加热正火处理适用于普通低合金钢和部分低 合金高强度钢,相当于X60钢级以下的焊管。焊缝感应加热退火 处理是将焊缝加热至700〜750°C双相区,随后空冷至常温,目的 是消除焊接内应力和改善塑性。退火处理主要用于碳素钢和部分普 通低合金钢焊管。这种工艺国内焊管生产线很少釆用。

-

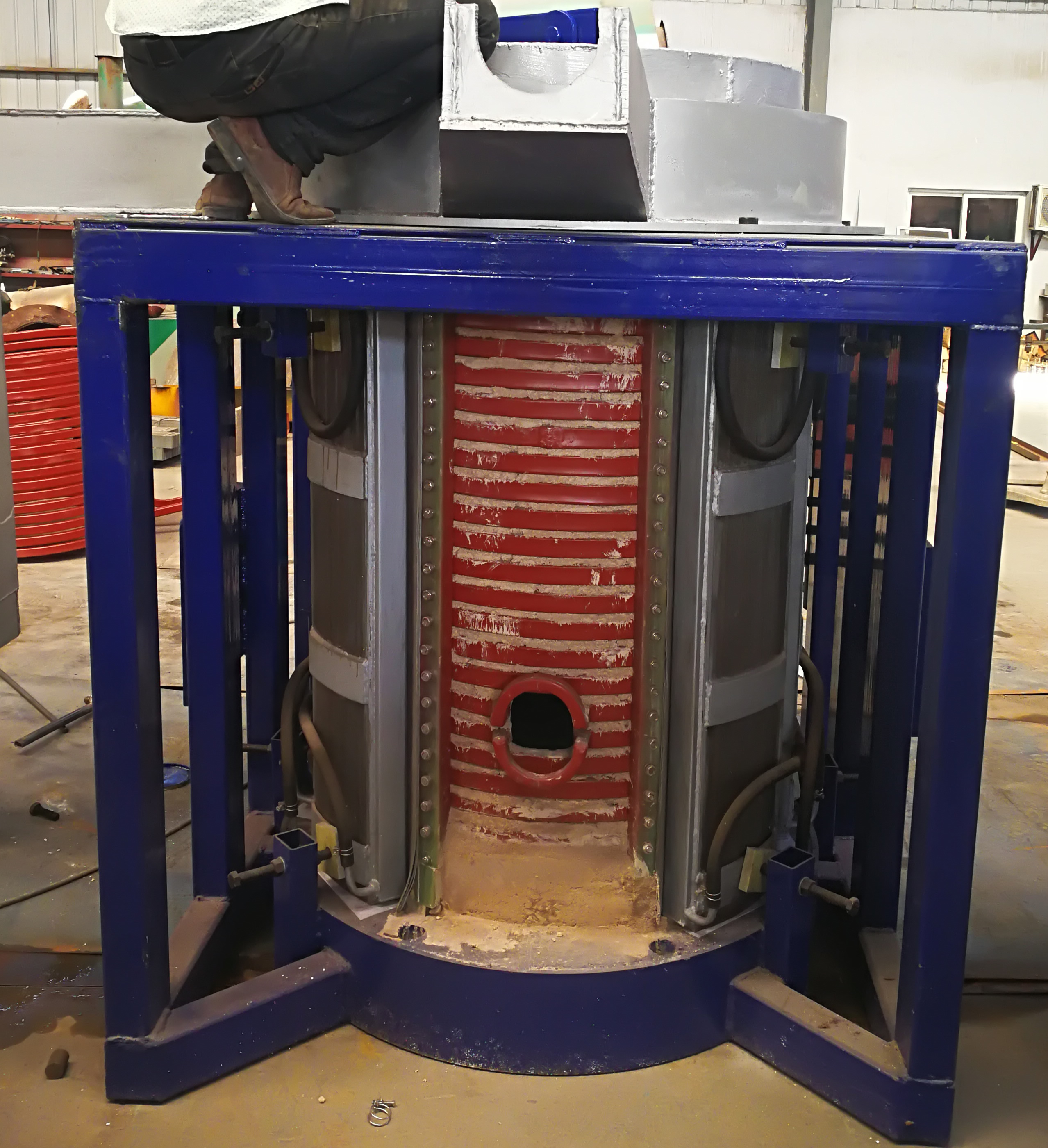

焊缝感应加热正火+回火处理正火处理后焊缝的硬度仍 高而塑性还低时,可以采取高温回火处理进行补救。感应加热回火 处理是将焊缝加热到Ad以下温度,通常为650℃左右后空冷。经 高温回火处理后原钢中马氏体组织转变为回火索氏体和铁素体,焊 缝的塑性提高,硬度下降,强度变化不大。焊缝采用的感应加热炉淬火十回火处理这种热处理方法又称调质处理,在线焊缝感应加热调质处理是目前最先进的热处理技术。经 调质处理后焊缝的综合力学性能完全达到管体的水平,实现焊缝与 管体性能均一化。实现这项热处理工艺技术的核心就是必须掌握横 向磁场加热技术,保证加热温度的均匀和准确。对于低合金高强度 钢和微合化高强度钢焊缝的淬火加热温度为900〜950℃,回火加 热温度为600〜650°C,淬火采用喷淋式冷却,回火釆用空冷与水 冷结合冷却。淬火、回火温度釆用纵向磁场加热时,控温的准确度 可以达到士 10°C,这是高强度焊管保持性能稳定必需的控温水平。 利用横向磁场加热焊缝同样要求高的控温精度•目前•国内尚处于 研发阶段,距此精度相差较大。不过可以相信会很快攻克这项加热技术,实现焊缝在线感应加热调质处理。

Induction heating welding seam heat treatment method

Pipeline steel is the main type of steel whose welds require heat treatment to improve mechanical properties. The steels used in different strength steel grades and their requirements for room temperature strength are listed in Table 6-2 . Based on the steel types and mechanical properties listed in Table 6-2 , the main heat treatment methods to improve the overall performance of welds include normalizing treatment, normalizing + tempering treatment, quenching + tempering treatment and other methods. At present, the weld normalizing treatment is mostly used in the production of domestic welded pipes, and other heat treatment methods have not yet been adopted. The most advanced weld heat treatment is the quenching and tempering production line . Normalizing treatment is mostly used in large-scale welded pipe production lines abroad, and quenching and tempering treatment is only used by individual companies in Japan and the European Union. Induction heating quenching and tempering treatment of welds is the direction of future development.

Table 6-2 Standard steel grade and room temperature strength of pipeline steel

|

GB/T 9711. 1-1997 Steel grade |

API spec 5L— 2004 Steel grade |

Mechanical properties at room temperature |

Steel |

|

|

%/MPa |

ffb /MPa |

|||

|

one |

A25 |

172 |

310 |

|

|

L210 |

A |

207 |

331 |

Carbon steel |

|

L245 |

B |

241 |

413 |

|

|

L290 |

X42 |

289 |

413 |

|

|

L320 |

X46 |

317 |

434 |

Ordinary low alloy steel |

|

L360 |

X52 |

358 |

455 |

|

|

L390 |

X56 |

386 |

489 |

|

|

L415 |

X60 |

415 |

517 |

Low-alloy high-strength steel |

|

L45O |

X65 |

448 |

530 |

|

|

L485 |

X70 |

482 |

565 |

|

|

L555 |

X80 |

551 |

620 |

Microalloyed high-strength steel |

|

— |

X100 |

727 |

837 |

|

(1) Weld induction heating normalizing treatment includes annealing treatment, sometimes called stress relief annealing. The induction heating normalizing process of the weld is to heat the weld to a temperature above Ae , and then air-cooled to below 400 °C and water-cooled to room temperature after 900~950°C . In this way, the internal stress of the welding is eliminated, the grain of the weld is refined, the microstructure is improved, and the plasticity and impact toughness of the weld are improved. Weld induction heating normalizing treatment is suitable for ordinary low-alloy steel and some low-alloy high-strength steels, equivalent to welded pipes below X60 steel grade. The welding seam induction heating annealing treatment is to heat the welding seam to 700 ~ 750°C dual-phase zone, and then air-cooled to room temperature, the purpose is to eliminate the internal stress of the welding and improve the plasticity. Annealing treatment is mainly used for carbon steel and some ordinary low-alloy steel welded pipes. This process is rarely used in domestic welded pipe production lines.

(2) Weld induction heating normalizing + tempering treatment After the normalizing treatment, when the hardness of the weld is still high and the plasticity is still low, high temperature tempering treatment can be used to remedy it. Induction heating and tempering is to heat the weld to a temperature below Ad , usually around 650 ℃ and then air-cooled. After the high temperature tempering treatment, the martensite structure in the raw steel is transformed into tempered sorbite and ferrite, the plasticity of the weld is improved, the hardness is reduced, and the strength changes little.Weld used induction heating furnace quenching and tempering treatment ten this heat treatment method, also known as quenching, quenching and induction heating line weld heat treatment is the most advanced technology. After quenching and tempering, the comprehensive mechanical properties of the welding seam completely reach the level of the pipe body, realizing the uniformity of the welding seam and the pipe body performance. The core of this heat treatment technology is to master the transverse magnetic field heating technology to ensure the uniformity and accuracy of the heating temperature. For low-alloy high-strength steel and micro-synthesized high-strength steel welds, the quenching heating temperature is 900 ~ 950 ℃ , the tempering heating temperature is 600 ~ 650°C, the quenching adopts spray cooling, and the tempering adopts air cooling and water cooling. Combine cooling. When the quenching and tempering temperature is heated by a longitudinal magnetic field, the accuracy of temperature control can reach ± 10°C, which is the necessary temperature control level for high-strength welded pipes to maintain stable performance. Using the transverse field heating welds also require high precision temperature control • currently • China is still in the development stage, from the accuracy of this large difference. However, it is believed that this heating technology will soon be overcome, and the weld seam will be heated and tempered by on-line induction heating.

手 机:15038554363