洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

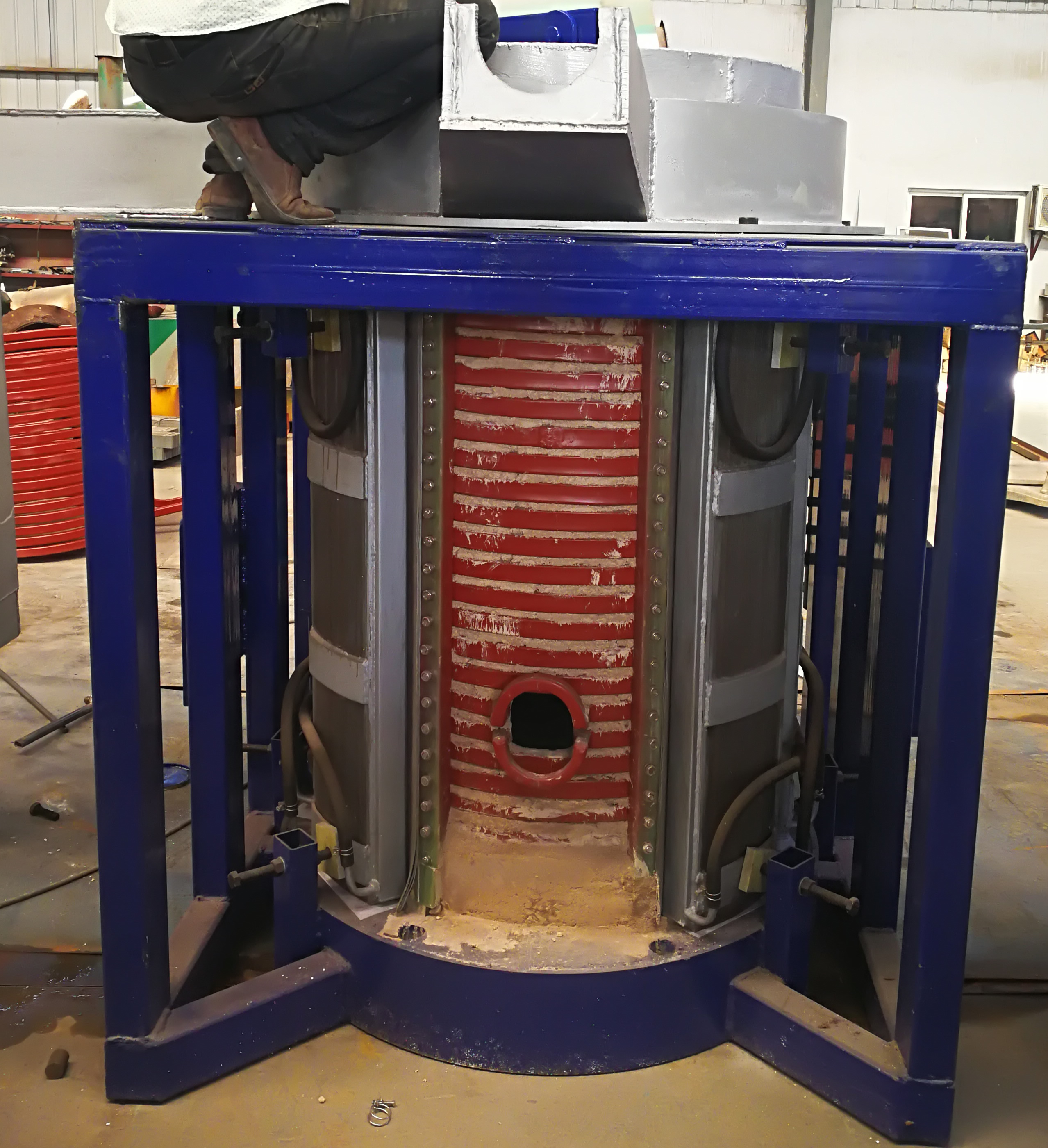

中频炉炉壁内衬粘渣解决方法

1、机械破除法

所谓的机械破除法,就是等炉衬粘渣出现后,采用机械的手段,比如铁锹,铁棍等刮去炉衬上的粘渣。机械破除法会使得炉衬上的粘渣易于刮除,常常会提高熔炼温度,使粘渣变软易于去除。但会增加额外的电耗,同时高温会导致炉衬的破坏,影响使用寿命。工人在刮除炉渣时,为了保证操作安全,又会降低电炉功率,而电炉功率的降低,会导致电效率的下降,实质就是导致熔炼电耗增加。

2、化学破除法

所谓的化学破除法是与机械破除法完全不同的方式,根据炉渣形成的原理,改变粘渣形成机制,从根本上破除炉衬粘渣的可能性。如果渣的凝固温度低于炉衬温度,则即使渣在上浮过程中与炉衬接触,炉衬温度降低也不会让渣的温度低于其凝固温度,从而避免炉渣在炉壁上凝固形成粘渣。

化学破除法正是利用这一原理,通过添加一些助剂,改变炉渣理化性能,降低其熔点。以前常用萤石来作为降低渣熔点的溶剂,但是单纯使用萤石的效果并不明显,并且会导致炉衬侵蚀,使用不当反而会加剧炉衬寿命下降。

3、防止积渣

必要时采取样品作化学分析及显微组织与矿物相分析,防止积渣要比去除挂渣容易。如果使用助熔剂的话,可能会损伤耐材炉衬,加快炉衬之熔蚀反应。若在低铁水液面除渣不易的话,可将铁水出清,在浇包中作除渣。

以上就是对于中频炉得到炉壁内衬粘渣如何处理这一问题的解答,如果不采取解决措施,炉壁上的渣会越来越厚,中频炉的炉容会越来越小,同时熔炼效率也会下降,造成严重后果。

Solution to sticky slag on the inner lining of induction furnace

1. Mechanical breaking method

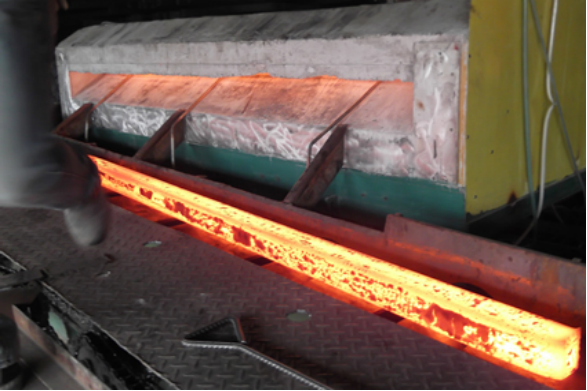

The so-called mechanical breaking method is to use mechanical means, such as shovels, iron rods, etc., to scrape off the slag on the furnace lining after the slag on the furnace lining appears. The mechanical breaking method makes the sticky slag on the furnace lining easy to scrape, and often increases the melting temperature, so that the sticky slag becomes soft and easy to remove. But it will increase additional power consumption, and high temperature will cause damage to the furnace lining and affect the service life. When workers scrape the slag, in order to ensure safe operation, they will reduce the power of the electric furnace, and the reduction of the power of the electric furnace will lead to a decrease in electrical efficiency, which essentially leads to an increase in smelting power consumption.

2. Chemical breaking method

The so-called chemical destruction method is completely different from the mechanical destruction method. According to the principle of slag formation, the formation mechanism of sticky slag is changed to fundamentally eliminate the possibility of sticky slag on the furnace lining. If the solidification temperature of the slag is lower than the temperature of the furnace lining, even if the slag contacts the furnace lining during the floating process, the temperature of the furnace lining will not drop below its solidification temperature, so as to prevent the slag from solidifying on the furnace wall to form sticky slag.

The chemical breaking method uses this principle to change the physical and chemical properties of the slag and lower its melting point by adding some additives. In the past, fluorite was commonly used as a solvent to lower the melting point of the slag, but the effect of using fluorite alone was not obvious, and it would cause corrosion of the furnace lining. Improper use would worsen the life of the furnace lining.

3. Prevent slag accumulation

When necessary, samples are taken for chemical analysis and microstructure and mineral phase analysis. It is easier to prevent slag accumulation than to remove slag. If a flux is used, it may damage the refractory lining and accelerate the corrosion reaction of the lining. If it is not easy to remove the slag on the liquid surface of the low molten iron, the molten iron can be cleaned out and used for slag removal in the ladle.

The above is the answer to the problem of how to deal with the sticky slag on the furnace wall lining of the induction furnace. If no measures are taken, the slag on the furnace wall will become thicker and thicker, the furnace capacity of the induction furnace will become smaller and smaller, and at the same time smelting Efficiency will also drop, causing serious consequences.

https://songdaokeji.cn/category/products/induction-melting-furnace

https://songdaokeji.cn/category/blog/induction-melting-furnace-related-information

Telephone:8615038554363

手 机:15038554363