洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

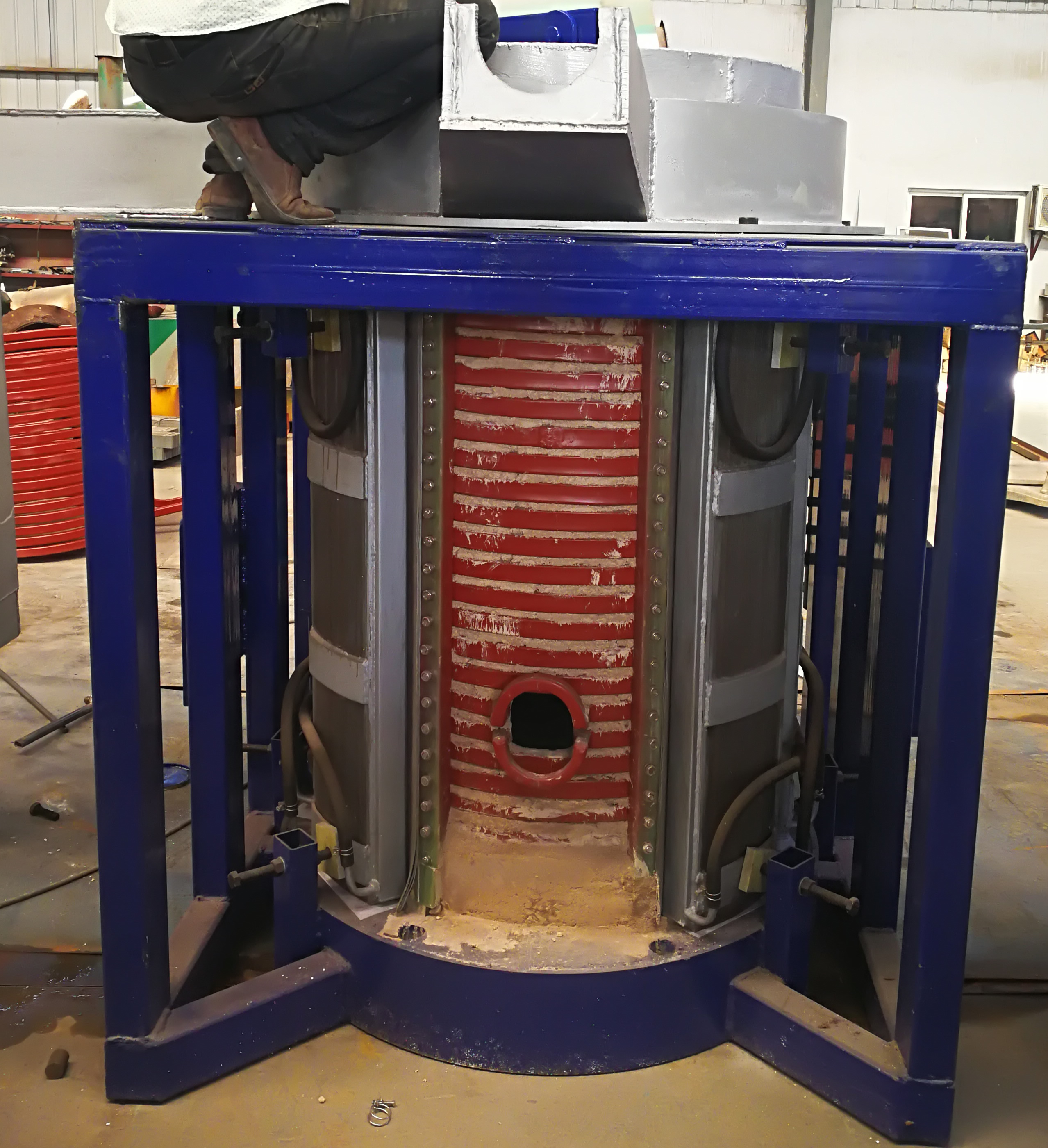

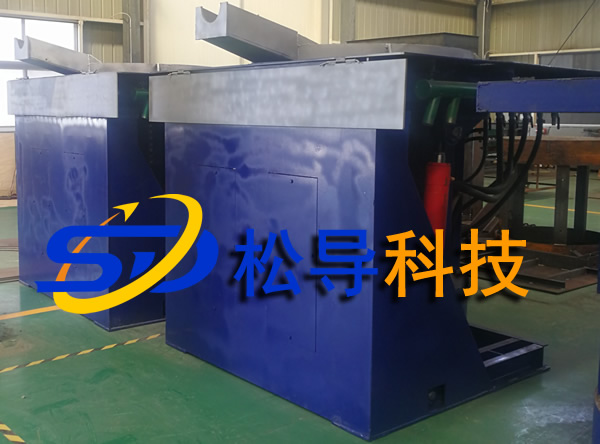

铜棒感应加热炉

设备名称:铜棒感应加热炉

设备功率:100—8000KW

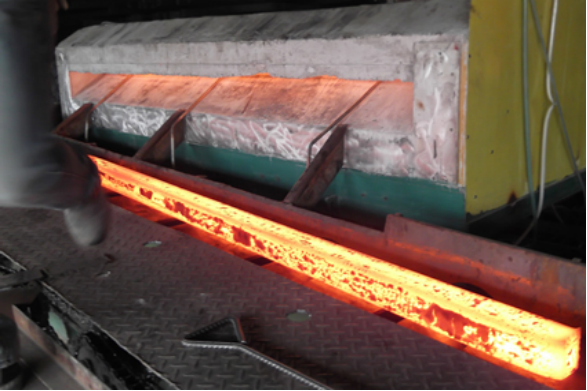

工件材质:铜棒

加热温度:根据客户需求调节

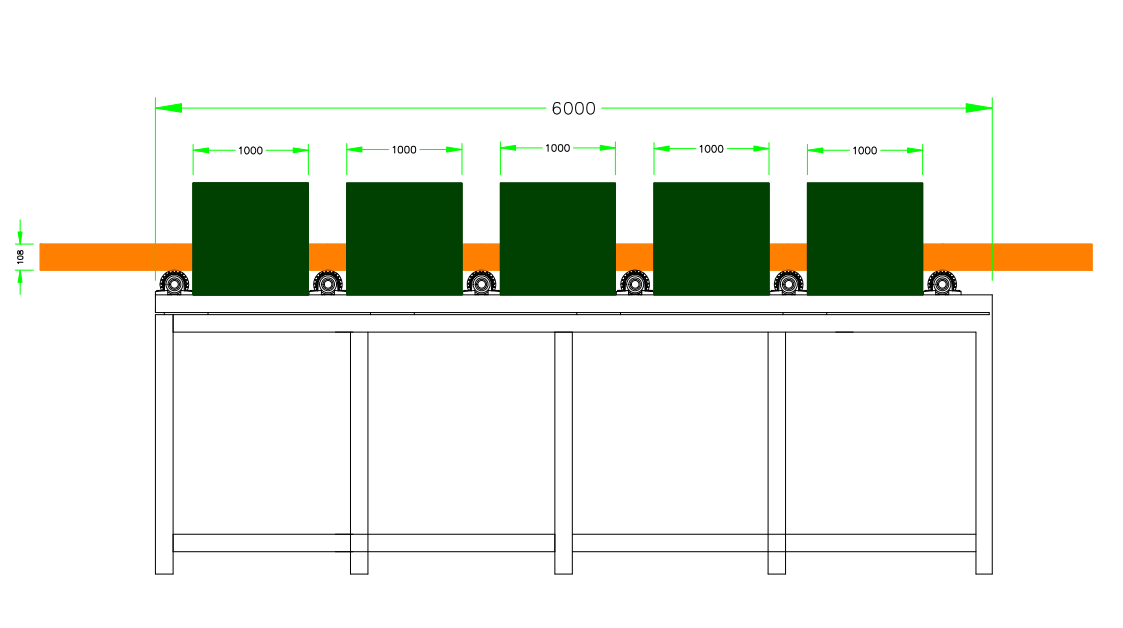

铜棒感应加热炉机械系统工作过程:

本成套设备机械动作采用PLC控制,只需人工将料框置于搓板上料机平台,其余动作均由PLC控制下的系统自动完成。可根据用户的每个产品规格设定一套程序,工作时只需在触摸屏上点击需要生产的产品规格一切动作均有PLC程序自动完成。

铜棒感应加热炉的特点:

1.中央控制电路板由计算机优化设计,单元电路优化组合,装置性能稳定,质量可靠、抗干扰性强;

2.元件布局协调合理、维修方便;

3.在零压启动的基础上又增加了自动扫频重复启动功能,电压及电流环电路紧密跟踪,设备启动及停止平滑稳定,无电流冲击。

4.逆变启动信号采用单信号高灵敏触发电路,进一步加大了设备的启动性能,使设备的启动成功率达到较高;

5.恒功率电路控制系统,在生产中随着炉料的变化快速的将电压和电流自动调控在可靠设定上,不需要人工调节逆变截止角;

6.透热锻造设备具有完善的过压、过流、欠压、缺水、缺相、限压限流等保护系统,从而保证了铜棒电加热设备的使用可靠性和工作稳定性;

7.高度集成化电路方案,调试和操作都快捷、简便、易学。

Copper rod induction heating furnace

Equipment Name: Copper Rod Induction Heating Furnace

Equipment power: 100—8000KW

Workpiece material: copper rod

Heating temperature: adjust according to customer needs

The working process of the mechanical system of the copper rod induction heating furnace:

The mechanical action of this complete set of equipment is controlled by PLC, only need to manually place the material frame on the washboard feeder platform, and the rest of the actions are automatically completed by the system under the PLC control. A set of programs can be set according to the user’s specifications for each product. When working, only the product specifications to be produced need to be clicked on the touch screen. All actions are automatically completed by the PLC program.

Characteristics of copper rod induction heating furnace:

1. The central control circuit board is optimized by the computer, the unit circuit is optimized and combined, the device performance is stable, the quality is reliable, and the anti-interference is strong;

2. Component layout is coordinated and reasonable, and maintenance is convenient;

3. On the basis of zero-voltage start, an automatic frequency sweep and repeat start function is added. The voltage and current loop circuits are closely tracked, and the equipment starts and stops smoothly and stably, without current impact.

4. The inverter start signal adopts a single-signal high-sensitivity trigger circuit, which further enhances the start-up performance of the equipment and makes the start-up success rate of the equipment higher;

5. The constant power circuit control system can quickly adjust the voltage and current to a reliable setting according to the change of the charge in the production, without the need to manually adjust the inverter cut-off angle;

6. Diathermic forging equipment has complete protection systems for overvoltage, overcurrent, undervoltage, water shortage, phase loss, pressure limiting and current limiting, so as to ensure the reliability and working stability of the copper rod electric heating equipment;

7. Highly integrated circuit scheme, debugging and operation are fast, simple and easy to learn.

手 机:15038554363