洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

中频炉与电渣重熔炉的区别

中频炉的原理:

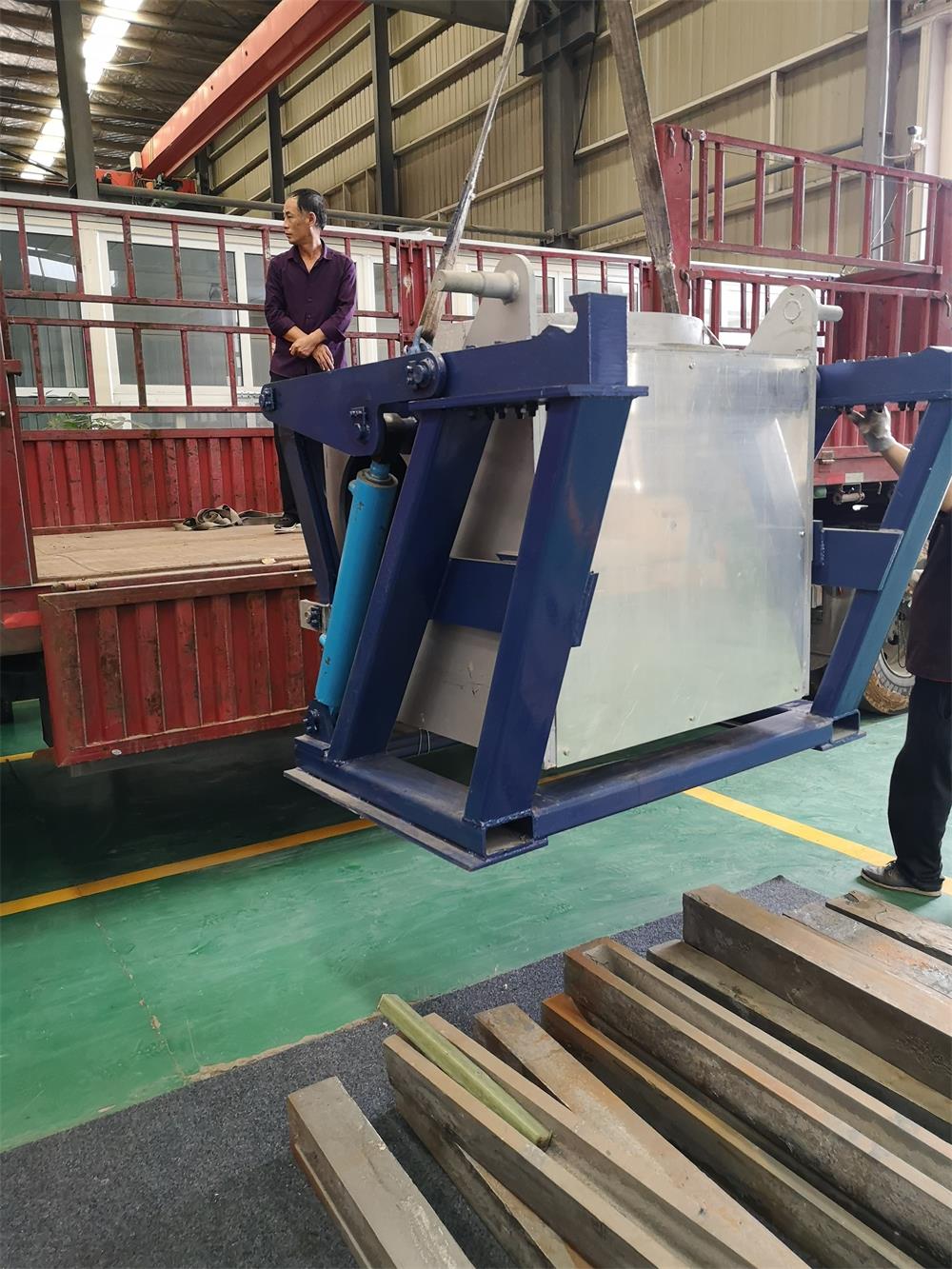

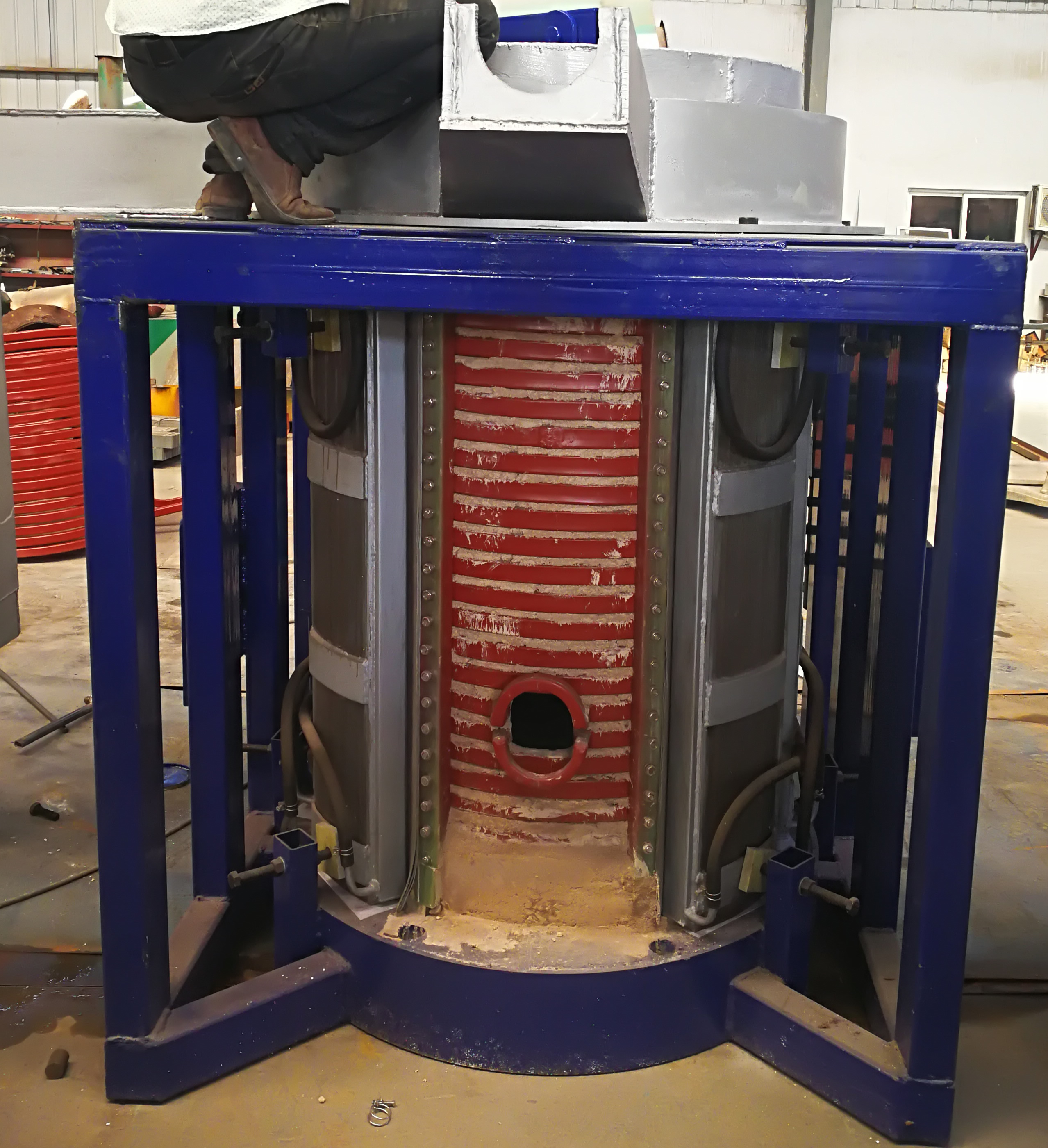

中频炉主要由电源、感应圈及感应圈内用耐火材料筑成的坩埚组成。坩埚内盛有金属炉料, 相当于变压器的副绕组, 当感应圈接通交流电源时, 在感应圈内产生交变磁场, 其磁力线切割坩埚中的金属炉料, 在炉料中就产生了感应电动势, 由于炉料本身形成一闭合回路, 此副绕组的特点是仅有一匝而且是闭合的。所以在炉料中同时产生感应电流, 感应电流通过炉料加热熔化。

中频炉的用途:

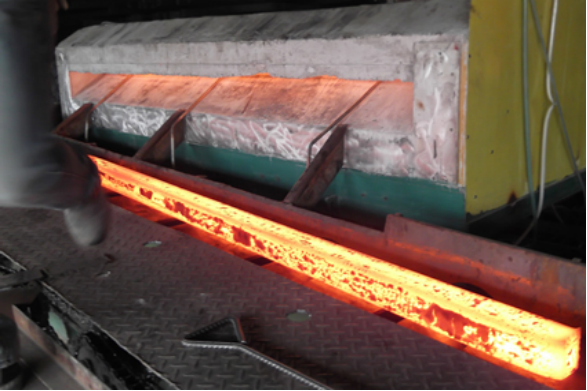

广泛用于有色金属的熔化、加热。如熔化生铁,普通钢、不锈钢、工具钢、铜、铝、金、银及合金等;中频炉加热装置具有体积小,重量轻、效率高、热加工质量优及有利环境等优点,正迅速淘汰燃煤炉、燃气炉、燃油炉及普通电阻炉,是新一代的金属加热设备。

电渣重熔炉原理:

电渣重熔炉是利用电流通过高电阻熔渣产生的热能对金属进行再熔炼的设备。电渣重熔一般是在大气压力下进行的,根据需要,也可配置真空机组进行真空精炼。

电渣重熔炉主要用途:

电渣重熔炉用途广泛,主要应用在钢铁行业、冶金行业等。采用不同渣料可用于精炼各种合金结构钢、耐热钢、轴承钢、锻模钢、高温合金、精密合金、耐蚀合金、高强度青铜以及其他铝、铜、铁、银等有色金属的合金;采用不同形状的结晶器可以直接生产大直径钢锭、厚板坯、中空管坯、大型柴油机曲轴、轧辊、大型齿轮、高压容器、炮管等优质铸钢件。

电渣重熔炉特点

1、由于存在熔滴与熔渣的冶金反应,去除非金属夹杂物效果好,重熔后金属纯度高、热塑性好。

2、一般用交流电,不需要真空,设备简单、投资少、生产成本低。

3、更适宜于生产大直径铸锭和异型铸锭。但电渣熔炼不适宜于精炼钦、错、铝等易氧化的金属。

4、对环境污染较大,须有除尘和去氟装置。

The difference between induction melting furnace and electroslag remelting furnace

Principle of induction melting furnace:

The induction melting furnace is mainly composed of a power supply, an induction coil and a crucible made of refractory materials in the induction coil. The crucible contains metal charge, which is equivalent to the secondary winding of the transformer. When the induction coil is connected to the AC power supply, an alternating magnetic field is generated in the induction coil. Since the charge itself forms a closed loop, the secondary winding is characterized by only one turn and is closed. Therefore, induced current is generated in the charge at the same time, and the induced current is heated and melted by the charge.

The purpose of induction melting furnace:

It is widely used in the melting and heating of non-ferrous metals. Such as melting pig iron, ordinary steel, stainless steel, tool steel, copper, aluminum, gold, silver and alloys, etc.; induction melting furnace heating device has the advantages of small size, light weight, high efficiency, excellent thermal processing quality and favorable environment, etc. Eliminating coal-fired furnaces, gas furnaces, oil-fired furnaces and ordinary resistance furnaces, it is a new generation of metal heating equipment.

Principle of electroslag remelting furnace:

The electroslag remelting furnace is a device that remelts metals by using the heat generated by the electric current passing through the high-resistance slag. Electroslag remelting is generally carried out under atmospheric pressure, and a vacuum unit can also be equipped for vacuum refining according to needs.

Main uses of electroslag remelting furnace:

Electroslag remelting furnaces are widely used, mainly in the steel industry and metallurgical industry. The use of different slag materials can be used to refine various alloy structural steels, heat-resistant steels, bearing steels, forging die steels, high-temperature alloys, precision alloys, corrosion-resistant alloys, high-strength bronzes, and other non-ferrous metals such as aluminum, copper, iron, and silver. Alloys; molds of different shapes can be used to directly produce high-quality steel castings such as large-diameter steel ingots, thick slabs, hollow tube billets, large diesel engine crankshafts, rolls, large gears, high-pressure vessels, gun barrels, etc.

Features of electroslag remelting furnace

1. Due to the metallurgical reaction between the molten droplet and the molten slag, the effect of removing non-metallic inclusions is good, and the metal purity after remelting is high and the thermoplasticity is good.

2. Generally AC is used, no vacuum is required, the equipment is simple, the investment is small, and the production cost is low.

3. It is more suitable for the production of large-diameter ingots and special-shaped ingots. However, electroslag smelting is not suitable for refining metals that are easily oxidized, such as titanium, aluminum, and aluminum.

4. The environment is highly polluted, and dust removal and defluorination devices must be installed.

手 机:15038554363