洛阳松导感应加热科技有限公司

联系方式:15038554363

24小时技术热线:15038554363

邮 箱:1390003299@qq.com

厂址:河南省洛阳市洛新工业园区

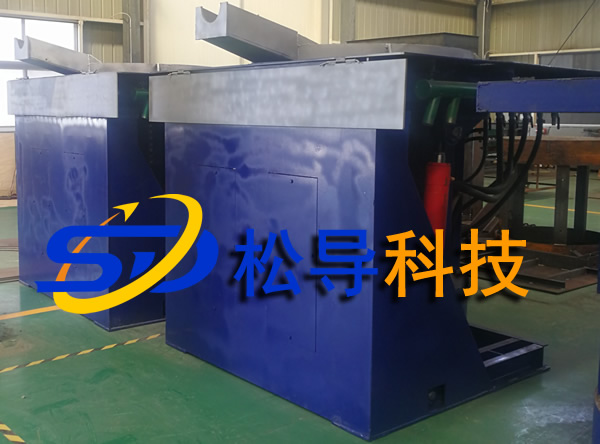

名称:钢管热处理生产线2020新型

价格:0

钢管热处理生产线2020新型

钢管热处理生产线是钢管在线感应加热设备,本设备系统将低温和高温加热分为两段,总体由2台3600KVA12脉波整流变压器、4台1500KW/(500、1000)Hz,中频电源、4台电容柜及4套感应器组成。合计总功率为6000KW。温度 自动控制系统由一台研华工业控制计算机、一台PLC(西门子S7-300型)、壹台红外测温仪、两套光电开关及壹台测速装置组成。

本钢管在线感应加热系统具有稳定可靠、控制精确、保护功能齐全等特点,可对被加热的钢管进行精确的温度控制,确保加热后的钢管温度及温差达到要求温度范围之内(±10℃)。

钢管在线感应加热具有良好的人机界面,可对运行中钢管的温度、速度等参数进行控制;对电源的频率、功率、钢管加热的温度、速度等参数进行显示;对钢管的温升、电源的功率分配等进行设定;对钢管各种状态参数如加热后温度、速度、钢管直径、壁厚、批号等参数进行记录,并定期向管理级发送。

一. 钢管在线感应加热工艺参数

1. 加热钢管规格

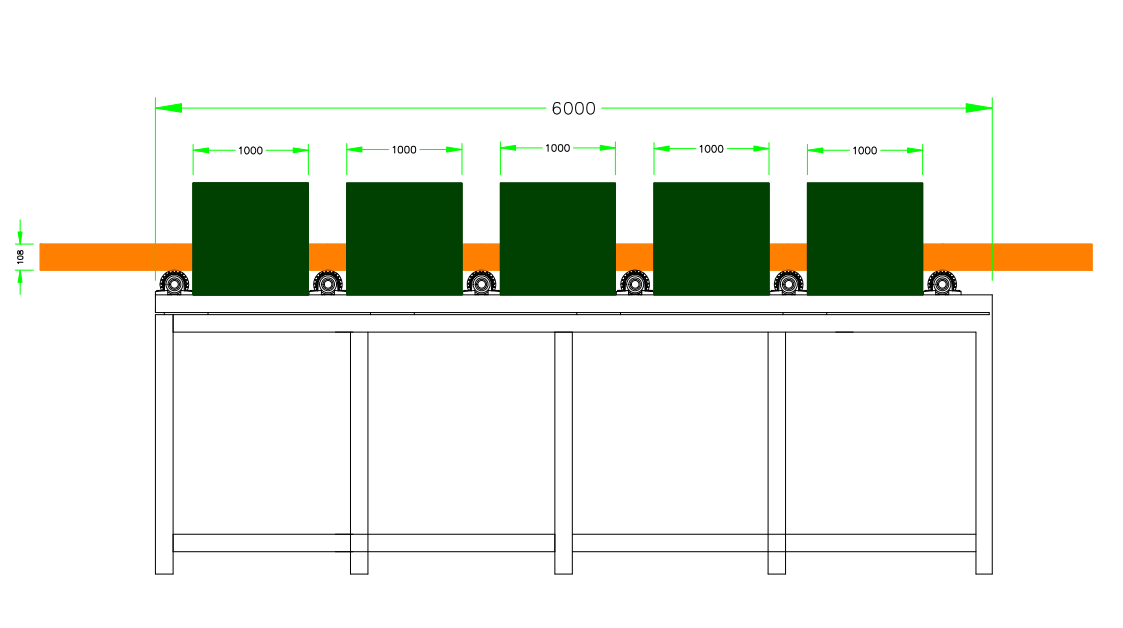

直径:φ108

壁厚:5

长度:25000

2. 钢管材质:碳钢、合金钢

3. 单支钢管Z大重量:315Kg,每米重量:12.62 Kg/m

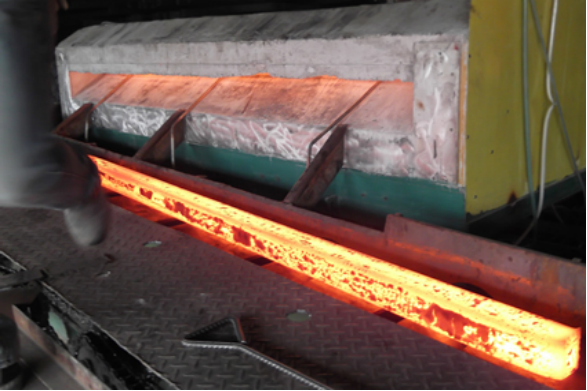

4. 钢管通过感应炉速度:30米/分钟

5. 钢管加热前温度:室温

6. 钢管加热后温度:1000℃

7. 加热后的钢管温度控制精度:±10℃

8. 加热后钢管头尾温度与钢管中部温度差:±10℃

二. 钢管加热的总体配置

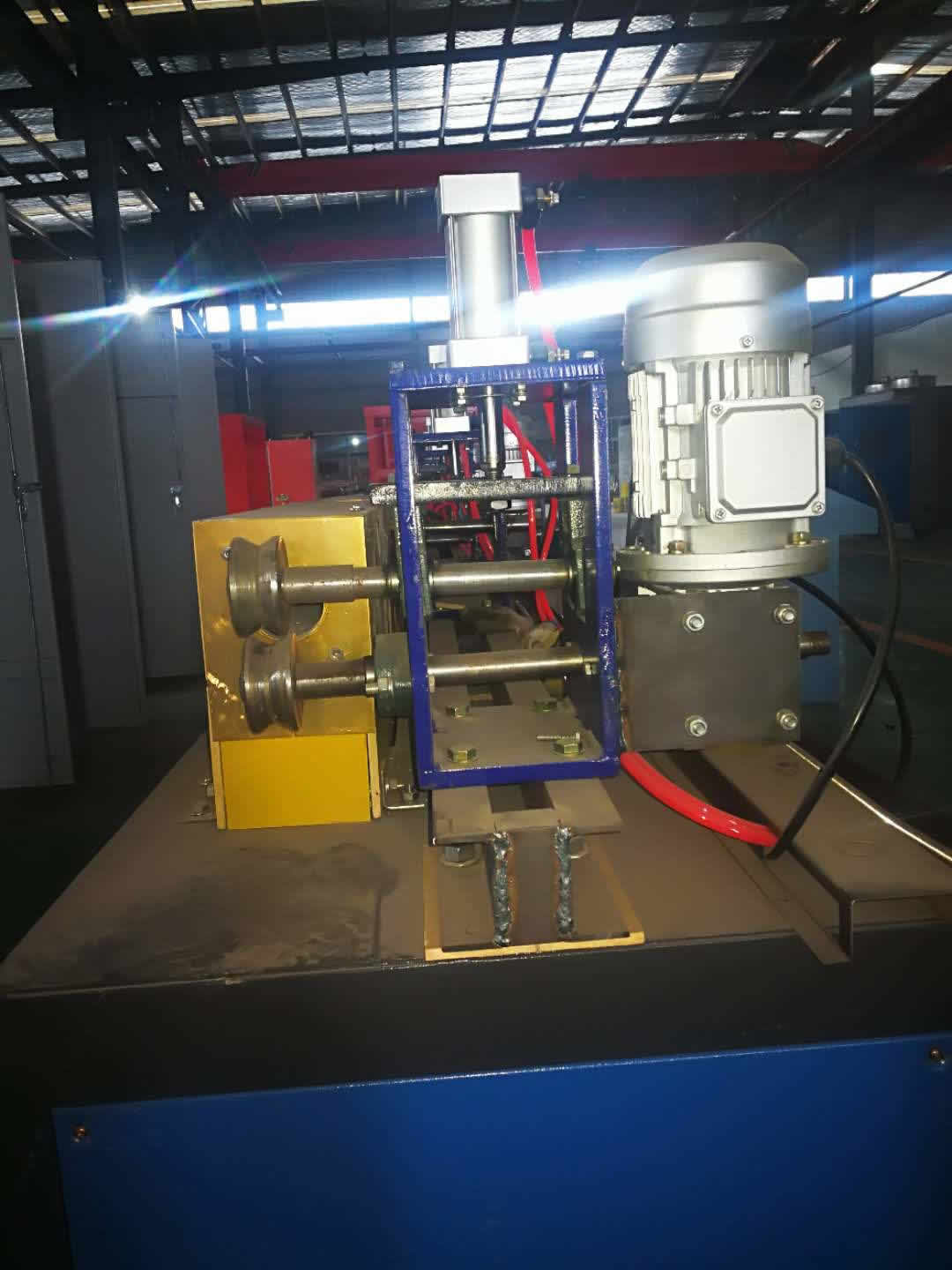

1. 钢管在线加热设备配置

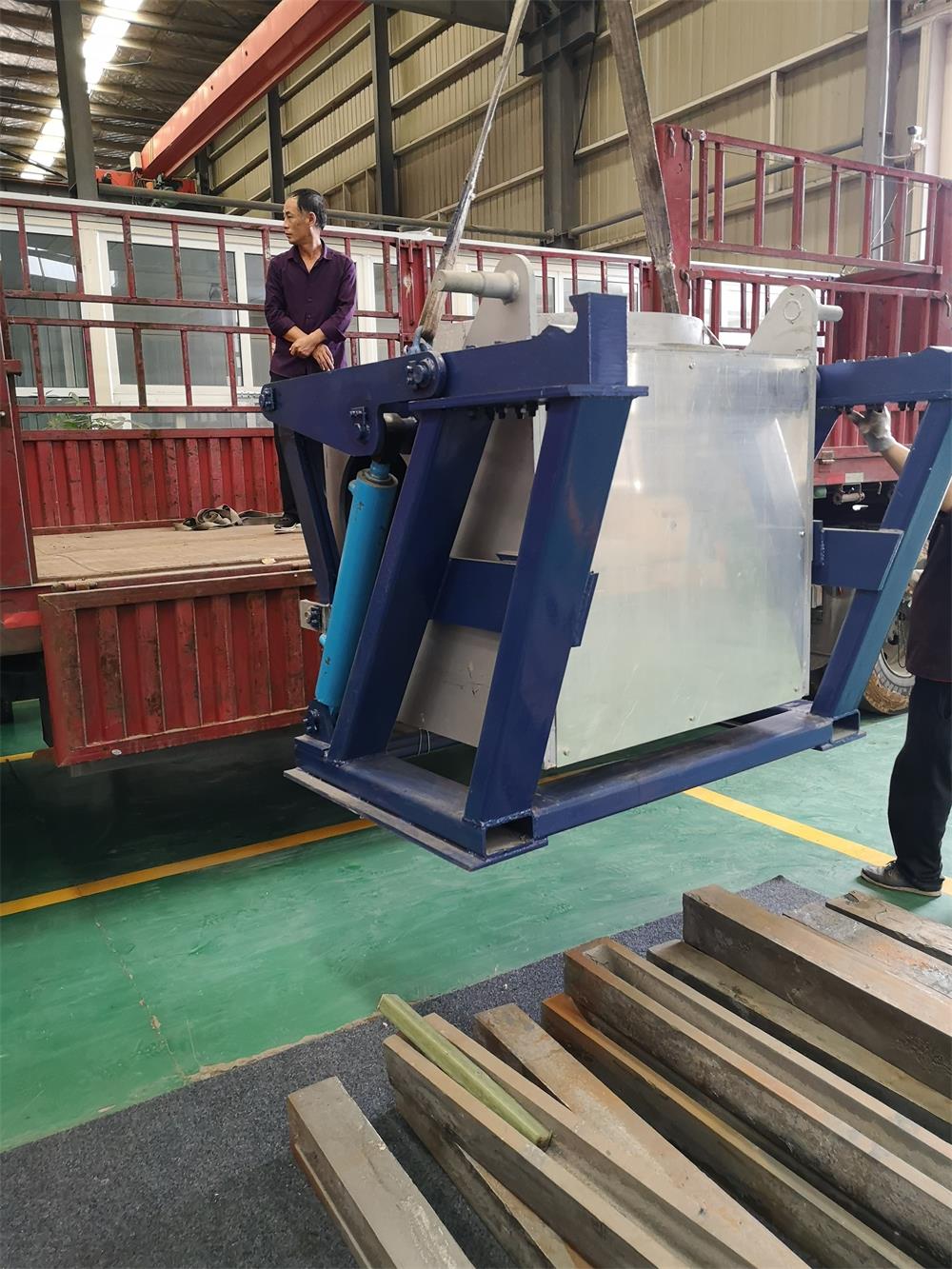

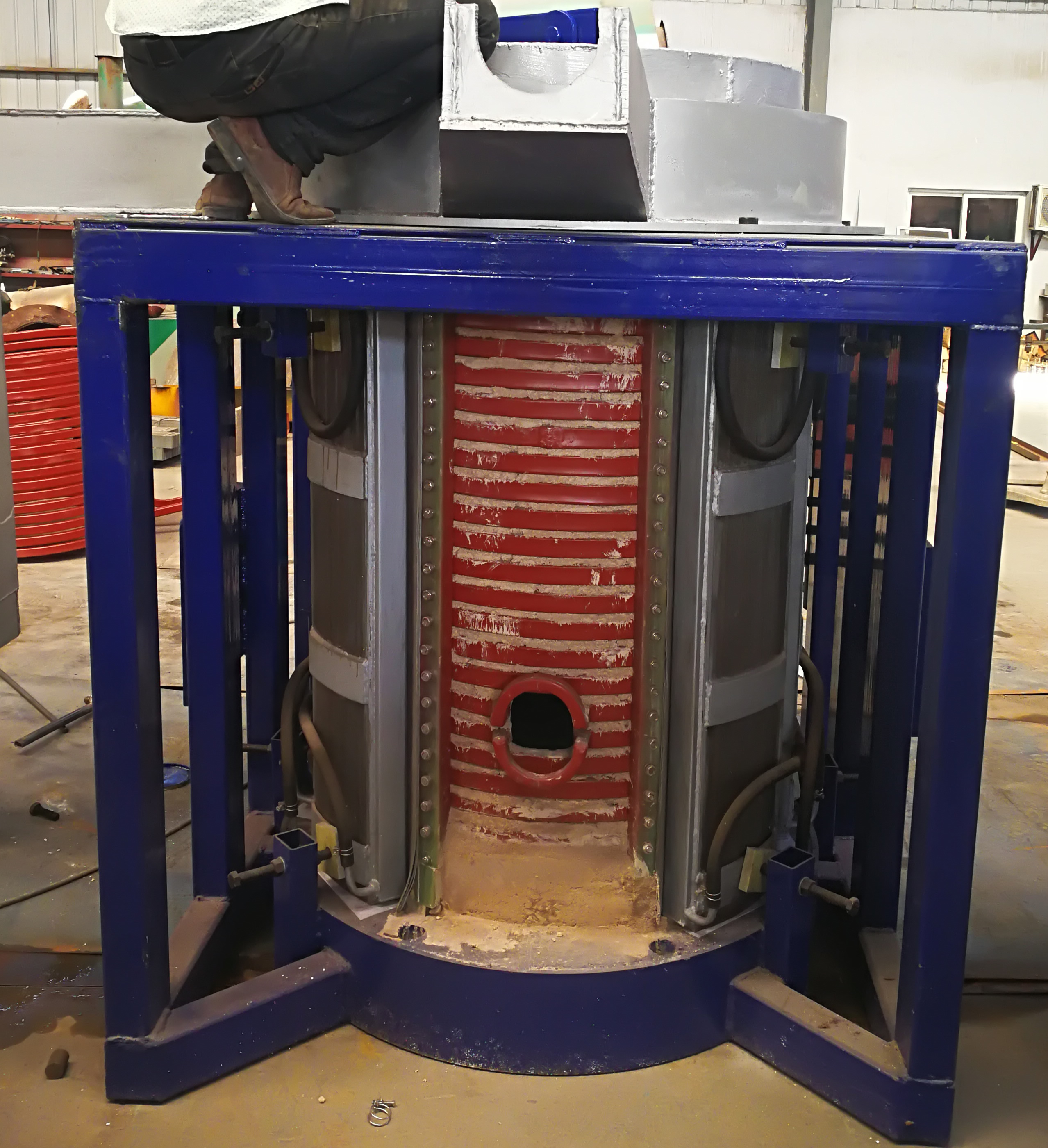

钢管定径前在线加热,采用组合式直通感应炉,设4个组合段,每个组合段包括一台中频电源,一台电容柜,低温加热每台采用2台感应器,高温加热每台采用3台感应器,感应器之间有运输辊道,使钢管按一定速度运行。系统供电采用2台12脉波整流变压器。整套设备由一套计算机控制系统进行控制,达到钢管加热要求。4台电源冷却系统采用4台风水冷却器。

2. 脉冲式快速感应加热工艺

所谓脉冲式快速感应加热是指钢管经10次短时间大功率密度的加热,并兼以保温和均温,达到减小温差的目的,这样在某种程度上就克服了热应力造成微观裂纹的危险。

这种方法适用于在线连续式加热,是目前国际上很先进的一种加热方法。

三、 钢管在线感应加热主要电气参数

1. 整流变压器(以下参数供需方采购时作为参考)

整套设备选用2台3600KVA的整流变压器,每台变压器为12脉波整流结构,每个输出端接一台中频电源。其主要参数如下:

额定容量:Sn=3600KVA

一次电压:U1=10KV 3φ 50Hz

二次电压:U2=660V、660V;

连接组别:d/d0,Y11

效 率:η≥ 98%

冷却方式:油浸自冷

保护功能:重瓦斯跳闸、轻瓦斯跳闸、压力释放闸、油超温报警

在高压侧带有±5%,0%三档调压

2. 中频电源主要参数

输入电压: 660V

直流电压: 890V

直流电流:1685A

中频电压:1300V

中频频率:1000Hz±10%和500Hz±10%

中频功率:1500KW/每台

3. 电容柜参数

1000Hz和500Hz电容器

型 号:RFM2 1.2—2000 —1.0(0.5)S

Steel pipe heat treatment production line

The steel pipe heat treatment production line is a steel pipe on-line induction heating device. The equipment system divides the low temperature and high temperature heating into two sections. The whole consists of two sets of 3600KVA12 pulse wave rectifier transformers, four sets of 1500KW/ ( 500 , 1000 ) Hz , medium frequency power supply and four capacitors. The cabinet and 4 sets of sensors are composed. The total total power is 6000KW . temperature The automatic control system consists of an Advantech industrial control computer, a PLC (Siemens S7-300 ), an infrared thermometer, two sets of photoelectric switches and a speed measuring device.

The on-line induction heating system of the steel pipe has the characteristics of stability, reliability, precise control and complete protection functions. It can accurately control the temperature of the heated steel pipe to ensure that the temperature and temperature difference of the heated steel pipe reach the required temperature range (± 10 °C). .

On-line induction heating of steel pipe has a good man-machine interface, which can control the parameters such as temperature and speed of the running steel pipe; display the parameters such as frequency, power, temperature and speed of heating of the steel pipe; temperature rise and power supply of the steel pipe The power distribution is set, etc.; various parameters of the steel pipe such as temperature, speed, steel pipe diameter, wall thickness, batch number and other parameters are recorded and sent to the management level periodically.

One. Steel pipe online induction heating process parameters

1 . Heating steel pipe specifications

Diameter: φ 108

Wall thickness: 5

Length: 25000

2 . Steel pipe material: carbon steel, alloy steel

3 . Single steel pipe Z large weight: 315Kg , weight per meter: 12.62 Kg/m

4 . Steel pipe through induction furnace speed: 30 m / min

5 . Steel pipe heating temperature: room temperature

6 . Steel pipe heating temperature: 1000 °C

7 . Temperature control accuracy of heated steel pipe: ± 10 °C

8 . After heating, the temperature between the head and tail of the steel pipe is different from the temperature in the middle of the steel pipe: ± 10 °C

two. Overall configuration of steel tube heating

1. Steel pipe online heating equipment configuration

Pipe diameter before heating given line, through combined use of an induction furnace, is provided to four of segments, each segment comprising a combination of a medium frequency power source, a capacitor bank, each low-temperature heating using two sensors, each using a high temperature heating There are 3 sensors, and there is a transport roller between the sensors to make the steel pipe run at a certain speed. The system power supply with two 12-pulse rectifier transformer. The whole set of equipment is controlled by a computer control system to meet the heating requirements of steel pipes. Four power cooling systems use four feng shui coolers.

2. Pulsed rapid induction heating process

The so-called pulsed rapid induction heating refers to the heating of the steel pipe through 10 short-time high-power density, and the purpose of reducing the temperature difference by heat preservation and uniform temperature, so as to overcome the thermal stress caused microscopic crack to some extent. Danger.

This method is suitable for online continuous heating and is a very advanced heating method in the world.

three, Steel pipe online induction heating main electrical parameters

1 . Rectifier transformer (the following parameters are used as reference for the purchase and purchase of the supplier)

Complete equipment selection of rectifier transformer 3600KVA 2, each 12-pulse rectifier transformer structure, each of a medium frequency power output termination. The main parameters are as follows:

Rated capacity: Sn=3600KVA

Primary voltage: U1=10KV 3 φ 50Hz

Secondary voltage: U2=660V , 660V ;

Connection group: d/d0, Y11

effect Rate: η≥ 98%

Cooling method: oil immersed from cold

Protection function: heavy gas trip, light gas trip, pressure release brake, oil over temperature alarm

± 5% on the high pressure side , 0% third gear

2 . Main frequency power supply parameters

Input voltage: 660V

DC voltage: 890V

DC current: 1685A

IF voltage: 1300V

IF frequency: 1000Hz ± 10% and 500Hz ± 10%

IF power: 1500KW / each

3 . Capacitor cabinet parameters

1000Hz and 500Hz capacitors

type No.: RFM2 1.2 — 2000 — 1.0(0.5)S

手 机:15038554363